ANSI #50B Plain Bore Duplex Stainless Steel Sprockets

- Model

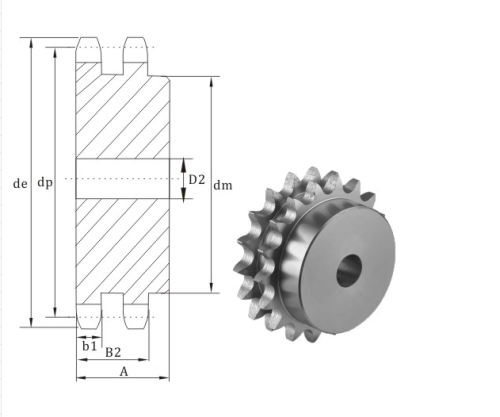

- #50-2 B Hub Sprockets

Item specifics

- Meterial

- Stainless Steel

- Color

- Silver

- Surface Treatment

- Blackening/Galvanizing/Phosphating

- Accuracy

- Precision teeth for optimum performance

- Quality

- Superior ANSI Sprocket

- Interchangeability

- Directly interchangeable with other brands

Review

Description

About #50B Plain Bore Duplex Stainless Steel Sprockets

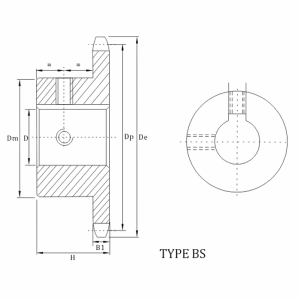

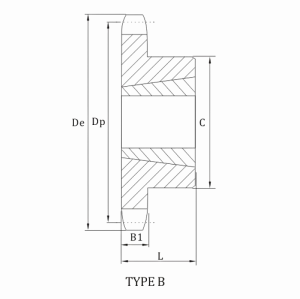

CTS® #50B Plain Bore Duplex Sprockets are crafted from premium stainless steel, these sprockets are engineered to surpass industry standards, providing unparalleled performance and durability. B Type Plain Bore Duplex Sprockets feature a hub on one side, enhancing their functionality and versatility. With a track record of excellence in manufacturing high-quality roller chain sprocket components, you can trust CTS® industrial expertise to deliver a top-tier product tailored to your unique application.

For quotation or other information on plain bore duplex sprockets, please contact us and we will be happy to help you.

Quality Assurance:

ISO9001: 2015 and GB/T24001-2016 / ISO14001: 2015.

Features

- High-precision Sprocket

- Durable Sprocket

- Directly interchangeable with other brands

- OEM Sprocket

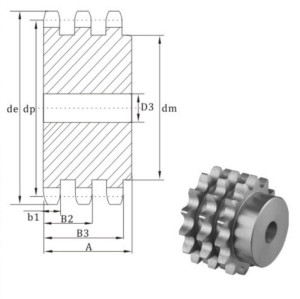

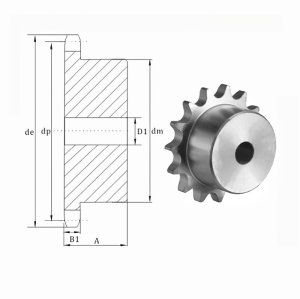

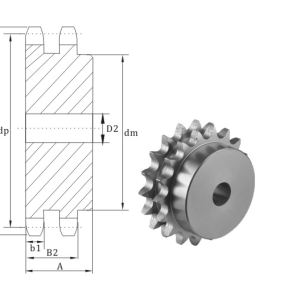

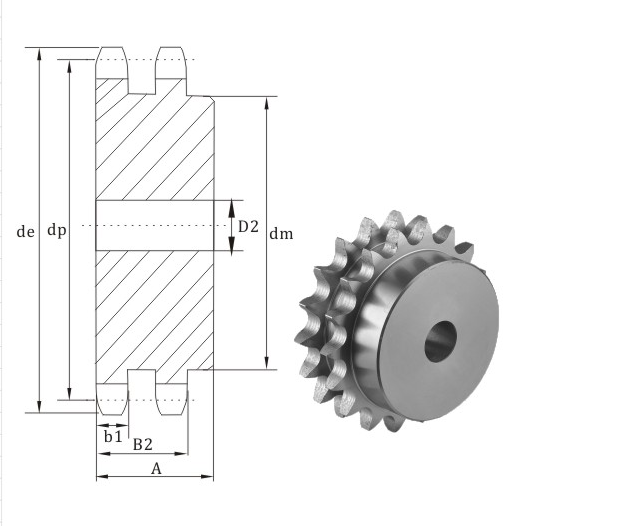

#50B Plain Bore Duplex Stainless Steel Sprocket Technical Data

|

Pitch

|

5/8"

|

|

Roller φ

|

0.400"

|

|

Tooth width b1

|

0.332"

|

Tooth width B2 | 1.045" |

Maximum bores shown will accommodate standard keyseat and setscrew over keyseat.

Slightly large bores are possible with no keyseat, shallow keyseat, or stescrew at angle to keyseat.