ANSI #40A Plain Bore Stainless Steel Sprockets

- Model

- #40 A Hub Sprockets

Item specifics

- Meterial

- Stainless Steel

- Color

- Silver

- Surface Treatment

- Blackening/Galvanizing/Phosphating

- Accuracy

- Precision teeth for optimum performance

- Quality

- Superior ANSI Sprocket

- Interchangeability

- Directly interchangeable with other brands

Review

Description

About #40A Plain Bore Stainless Steel Sprockets

CTS® ANSI #40A Plain Bore Stainless Steel Sprockets provide unparalleled durability and performance, meticulously engineered for industrial applications. Our A hub sprockets, crafted from premium 304 stainless steel materials, ensure dependable power transmission within sprocket systems. Our #40A plain boresprockets adhere to ANSI standards, these sprockets offer completely compatibility and efficient operation across diverse machinery setups. Rely on our expertise to deliver superior sprocket solutions that meet your industrial needs with excellence.

For quotation or other information on A-plate sprockets, please contact us and we will be happy to help you.

Quality Assurance:

ISO9001: 2015 and GB/T24001-2016 / ISO14001: 2015.

Features

- High-precision Sprocket

- Durable Sprocket

- Directly interchangeable with other brands

- OEM Sprocket

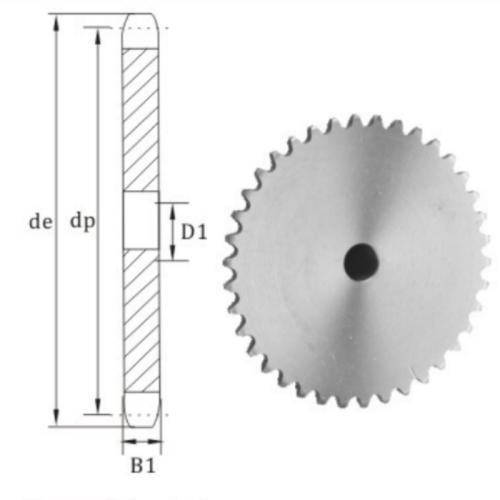

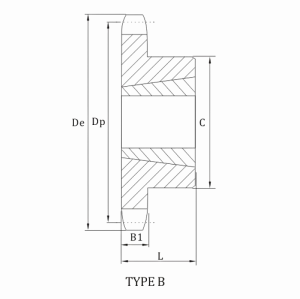

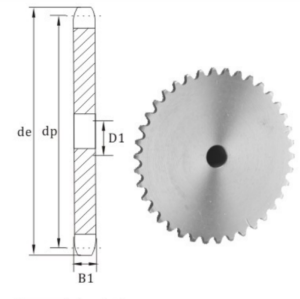

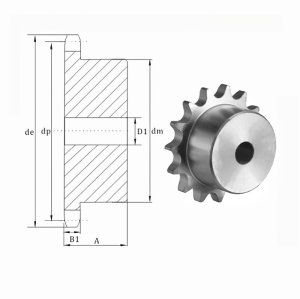

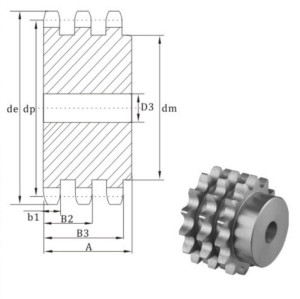

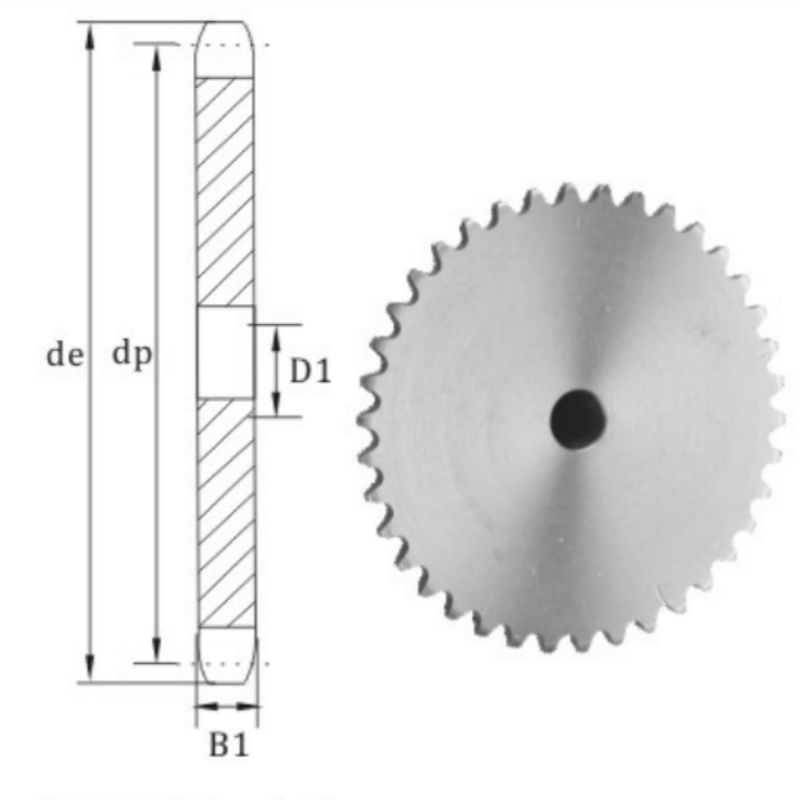

#40A Plain Bore Plate Wheel Stainless Steel Sprocket Technical Data

|

Pitch

|

1/2"

|

|

Roller φ

|

0.312"

|

|

Tooth width B1

|

0.284"

|

Slightly large bores are possible with no keyseat, shallow keyseat, or stescrew at angle to keyseat.