ANSI 35B Sprocket With Split Taper Bushing

- Model

- 35B Sprockets

Item specifics

- Material

- Carbon Steel

- Color

- Black

- Surface Treatment

- Blackening/Galvanizing/Phosphating

- Accuracy

- Precision teeth for optimum performance

- Quality

- Superior ANSI Sprocket

- Interchangeability

- Directly interchangeable with other brands

Review

Description

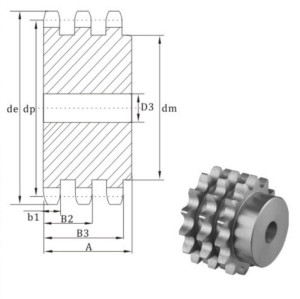

About 35B Sprockets with Split Taper Bushings

35B sprockets with split taper bushings are designed for easy installation and removal on shafts of varying diameters, making them highly versatile for different applications. The split taper bushing system allows for a tighter grip on the shaft compared to taper-lock sprockets, which is particularly beneficial in high-torque scenarios. They are typically used in conjunction with ANSI standard roller chains to suit different operational requirements. The design often includes a keyway to fit a corresponding key on the bushing, ensuring secure attachment and efficient torque transmission.

For a quotation or other information on #35B sprockets, please contact us and we will be happy to help you.

Quality Assurance:

ISO9001: 2015 and GB/T24001-2016 / ISO14001: 2015.

Features

- High-precision Sprocket

- Durable Sprocket

- Directly interchangeable with other brands

- OEM Sprocket

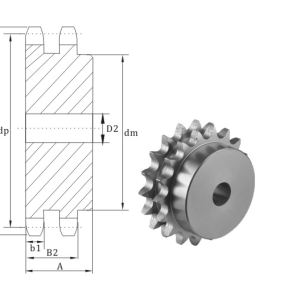

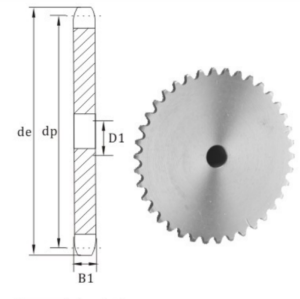

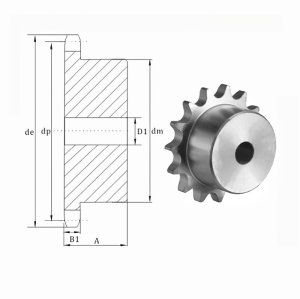

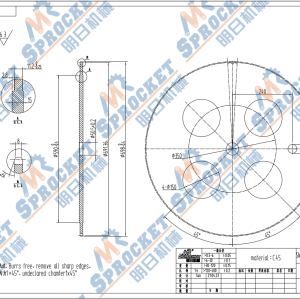

35B Sprocket with Split Taper Bushings Technical Data

|

Pitch

|

3/8"

|

|

Roller φ

|

0.200"

|

|

Tooth width B1

|

0.168"

|