1. Misalignment Issues

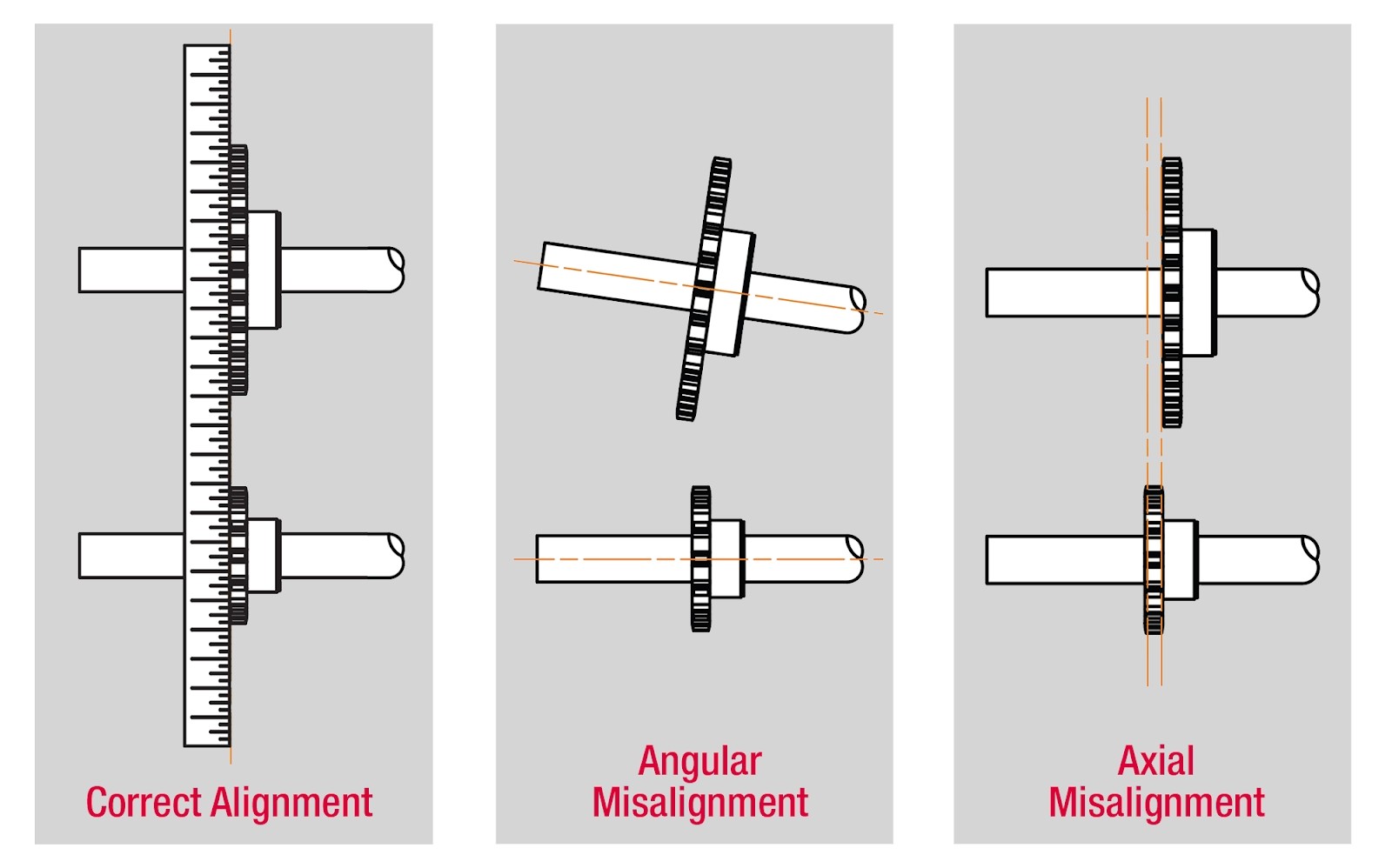

Sprocket Misalignment: When the sprockets are not properly aligned, the chain runs unevenly, causing excessive noise and vibration.

Shaft Misalignment: If the drive and driven shafts are not aligned, the chain may experience side forces, leading to irregular movement.

2. Improper Chain Tension

Over-Tensioned Chain: Too much tension increases friction and causes noise due to excessive wear.

Loose Chain: A slack chain can create a whipping effect, leading to vibration and impact noise.

3. Worn or Damaged Components

Worn Sprocket Teeth: If the sprocket teeth are worn or deformed, the chain engagement becomes uneven, causing rattling sounds.

Elongated Chain: Over time, chains stretch due to wear, leading to poor fit on the sprockets and increased vibration.

Damaged or Deformed Links: Bent or cracked chain links can result in irregular motion and noise.

4. Poor Lubrication

Insufficient Lubrication: Dry or poorly lubricated chains generate more friction, leading to squeaking or grinding sounds.

Excessive Lubrication: Too much lubricant can attract dust and debris, leading to contamination and wear.

5. Improper Sprocket Design or Selection

Incorrect Chain-Sprocket Match: Using the wrong chain pitch or type for the sprocket can result in poor engagement and noise.

Improper Tooth Profile: Inconsistent or rough tooth profiles can cause irregular chain movement.

6. Contamination and Foreign Particles

Dirt, Debris, or Metal Shavings: Foreign particles between the chain and sprocket increase wear and noise.

Corrosion and Rust: A rusted chain or sprocket surface leads to rough engagement and vibration.

7. High-Speed Operation without Proper Damping

Excessive Speed: Running the chain at high speeds without proper tensioners or dampers can lead to oscillations and vibration.

Sudden Load Changes: Frequent start-stop cycles or variable loads can cause impact forces, leading to noise and vibration.