When to Use Welded Steel vs. Drop Forged in Your Silo

- Share

- Issue Time

- Dec 19,2025

Summary

When to use Welded Steel vs. Drop Forged chains in grain storage and handling systems.

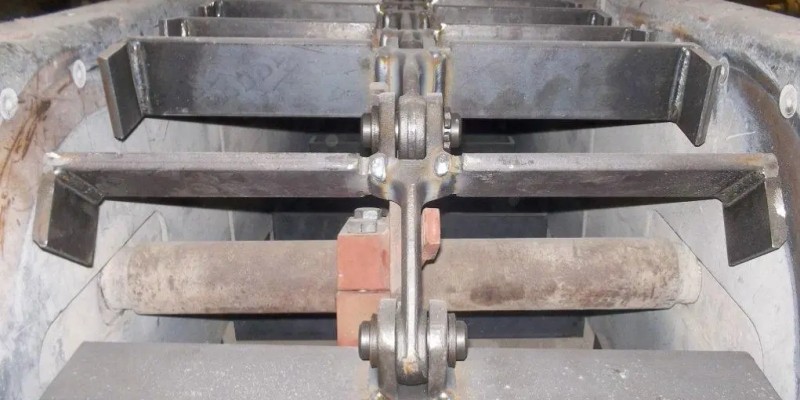

In the grain handling industry, the chain is the "backbone" of the operation. Whether you are moving grain from a receiving pit or distributing it across a 100,000-bushel silo, the type of chain you select determines your system's efficiency and lifespan. The two most common choices for heavy-duty grain conveyance are Welded Steel Chains and Drop Forged Link Chains.

The Engineering Challenge: Why Chain Choice Matters

A grain silo is a high-abrasion, high-dust environment. Unlike a standard factory conveyor, a grain conveyor must deal with "En-Masse" flow—where the grain itself acts as a weight and a grinding agent.

Choosing the wrong chain doesn't just mean a shorter lifespan; it can lead to "chain stretch," where the pitch of the chain increases due to wear at the pin-and-bushing joint. When this happens, the chain no longer fits the sprocket, leading to jumping, vibration, and eventually, a catastrophic snap.

Welded Steel Chain

Welded Steel Chains (often referred to as the WH or WR series) are the most common choice for "drag" conveyors in agricultural applications.

• Offset Sidebar Design: Most grain-handling welded chains use an "offset" sidebar. This allows for more flexibility and makes it easier to add attachments like Paddles or Flights that push the grain.

• Material Strength: High-quality manufacturers use 1045 Carbon Steel for the sidebars and Alloy Steel for the pins.

The WR Series welded steel chain is known for its heat-treated pins, which offer additional strength.

The WH Series welded steel chains feature fully heat-treated components, which provide superior tensile strength and greater resistance to wear and tear.

Drop Forged Link Chains

Drop Forged Chains (also known as Scraper Chains) are often considered the "top-tier" option for high-capacity grain handling. Unlike welded steel chains, each link in a drop forged chain is forged from a single piece of alloy steel.

• No Welds: There are no welded joints to fail. The entire link is a solid piece of heat-treated steel.

• Materials: Typically made from 20CrMnTi or similar high-grade alloys, then carburized (case-hardened) to a high Rockwell hardness.

• The Bushing-less Design: The pin rotates directly against the forged link, which is specially machined to provide a large bearing surface.

Welded Steel vs. Drop Forged Chain

| Feature | Welded Steel Chain(WH series) | Drop Forged Chain(Scraper) |

| Manufacturing | Fabricated & Welded | Forged Single-piece |

| Tensile Strength | High | Very High |

| Abrasion Resistance | Good (with hardened pins) | Excellent (Carburized) |

Cost | More Eco | |

Maintenance | Requires regular monitoring of welds | Highly resistant to stretch |

Best Use Case | Wide, Horizontal Dragging | High-capacity, long distance |

The "Wear Life" Factor

In grain storage, "wear life" is measured by how long the pin stays tight inside the joint.

Welded Steel Chain

Welded Steel relies on the weld integrity. If the weld cracks due to vibration, the link fails.

Supporting the System: Pulleys, Sprockets, and Bearings

Even the best chain will fail if the surrounding power transmission parts are of low quality. As a supplier, we recommend a "Total Drive" approach.

The Role of Sprockets

For both welded steel and drop forged chains, the Sprocket is the primary wear part.

We recommend a hardness of HRC 45-55. This ensures the sprocket doesn't "hook," which is the main cause of chain jumping.

Split Sprockets: Especially for the head shaft of a silo elevator, a split sprocket is essential. It allows you to change the sprocket without removing the chain or the shaft, saving hours of labor.

Precision Roller Chains (RC Series)

While welded and forged chains move the grain, Precision Roller Chains (RC-100 to RC-240) move the machinery. These connect the motor to the conveyor.

V-Belt Pulleys for Aeration

Don't forget the drying and aeration fans. These are driven by V-belt Pulleys (Sheaves).

Dynamic Balance: A fan running at 1800 RPM must be perfectly balanced. Our pulleys are dynamically balanced to prevent vibration, which protects the motor's internal bearings from premature failure.

The Importance of Bearing Units

Pillow Block Bearings support the shafts that hold your sprockets.

In a grain bin, dust is everywhere. We provide bearings with Triple-Lip Seals. This creates a "labyrinth" that prevents fine-grained dust from entering the bearing race.

A seized bearing creates friction and heat, which is a major fire risk in a dusty silo. Using high-quality, sealed bearing units is a critical safety measure.

Choose CTS® | Your Partner in Power Transmission

At our facility, we don't just sell parts; we provide solutions for the grain industry. Whether you need a WH132 Welded Steel Chain for a receiving pit or a Carburized Drop Forged Chain for your distribution system, we have the engineering expertise to help you make the right choice.

Ensure your harvest is successful by upgrading to transmission parts that are built for the reality of the grain silo.

Visit our [Grain Storage Solution] section to learn more about how we power transmission parts for every stage of grain handling, from receiving to aeration.

Ready for a Quote?

Contact us today for technical specifications on our full range of Chains, Sprockets, Bearings, and V-belt pulleys.