Welded Steel Chain

- Share

- Issue Time

- Dec 23,2024

Summary

This guide will talk about Welded Steel Chain

Welded Steel Chain

Welded steel chains are made from individual links of steel that are welded together, providing a strong and durable connection. Unlike traditional chains that use pins or other connecting mechanisms, welded steel chains are often more resistant to wear and corrosion, making them suitable for heavy-duty applications. Welded steel chains are designed to withstand extreme conditions, such as high temperatures, heavy loads, and rough environments.

Welded Steel Chain Type

The WR Series welded steel chain is known for its heat-treated pins, which offer additional strength.

The WH Series welded steel chains feature fully heat-treated components, which provide superior tensile strength and greater resistance to wear and tear.

While both the WR and WH Series welded steel chains are designed for heavy-duty use, the WH Series welded steel chain offers better overall performance due to its higher tensile strength and precision. The WR Series welded steel chain, however, is typically more cost-effective and sufficient for less demanding applications.

Welded Steel Chain Dimension

WR - Welded steel mill chain - only pins & bushes heat-treated

WH - Welded steel mill chain - all heat-treated

Welded Steel Chains and Sprockets

As a professional chain and sprocket manufacturer, CTS® not only has welded steel chains but also manufactures welded steel chain sprockets that match them. If you have any needs, please contact us and our technicians are happy to help you.

Welded Steel Mill Chain

Welded Steel Mill Chain Sprocket

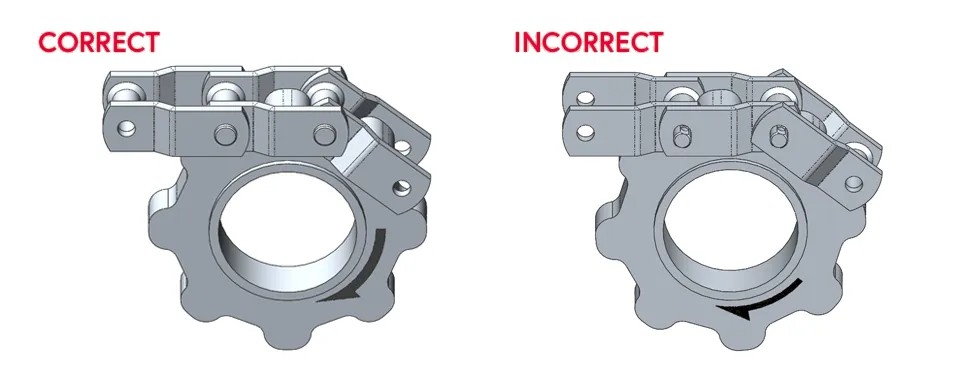

To extend the life of conveyor and elevator chains, it is crucial to ensure the correct direction of travel for all offset sidebar cast or bushed chains without rollers. The chain should move with the open end of the link facing forward. This helps prevent frictional wear between the link and the driving sprocket teeth.

As shown in the diagram, if the closed end of the link leads, the link will rotate on the driving tooth as the sprocket moves. However, when the chain is in the correct position, with the open end of the link leading, the following link simply moves on its pin as the sprocket wheel turns.

Applications of Welded Steel Chains

Conveyor System

Welded steel chains are often used in conveyor systems and are crucial for transporting goods because they can handle the repetitive movement of heavy materials without breaking down.

Heavy-duty Industry

Welded steel chains are used for logging operations, moving timber, and transporting materials through rough and challenging terrain.

Choose CTS® Welded Steel Chain

✔ Efficiency

Our high-quality palm oil chains improve efficiency, less downtime, and smoother operations.

✔ Durability

Manufactured from hardened steel, our palm oil chains are durable and require fewer replacements.

CTS®-ChinaTransmissionS is a professional agricultural chain manufacturer in the power transmission industry. As an experienced agricultural chain supplier, we manufacture Welded Steel Mill Chains with high-quality steel material. Besides standard agricultural chains, we can also provide customized agricultural chains for your application.

We offer a wide range of industrial transmission chain options: drop forged rivet-less chains, welded steel chains, 81X lumber conveyor chains, roller chains, conveyor chains, heavy-duty roller chains, etc.

If you have any questions about industrial transmission chains, please contact us to help you.

Professional Chain Manufacturers

With years of experience, we understand the needs of your application.

Various chain attachments

Attachments are commonly used for agricultural roller chains, we can supply complete chain attachment options.

High Standards of Quality Control

Our rigorous quality checks ensure every chain meets the highest standards.