Top 5 Factors to Consider When Choosing an Industrial Sprocket Manufacturer

- Share

- Issue Time

- Nov 19,2024

Summary

This guide will show you the top 5 factors to consider when choosing an industrial sprockets manufacturer.

Industrial sprockets are integral to power transmission in machinery, ensuring smooth operation in conveyor systems, automotive setups, and industrial equipment.

Selecting the right industrial sprocket manufacturer can impact product performance, durability, and overall efficiency.

Industrial Sprocket Manufacturing Expertise

An experienced industrial sprocket manufacturer brings precision industrial sprockets and knowledge. Industrial sprocket manufacturers specializing in industrial chain sprockets often utilize high-grade materials and advanced machining techniques to meet specific application needs, from small-scale conveyor setups to heavy-duty machinery.

Industrial Sprocket Customization Capabilities

Standard industrial sprockets may not always meet unique industrial demands. Look for a manufacturer that offers customization options, such as specific tooth profiles, bore sizes, and materials. For instance, idler sprockets or taper lock sprockets are often essential for specialized applications.

Industrial Sprockets Material Quality and Durability

Durable industrial sprockets minimize operational downtime. High-quality materials, such as hardened steel, ensure strength and reduce wear and tear. Industrial sprocket surface treatments like black oxidation or quenching further enhance resistance to environmental conditions

Industrial Sprockets Technological Advancements

Top industrial sprocket manufacturers leverage the latest CNC machining and digital design technologies. These innovations ensure consistent accuracy and reduce production errors, making the sprockets reliable for high-stress industrial environments

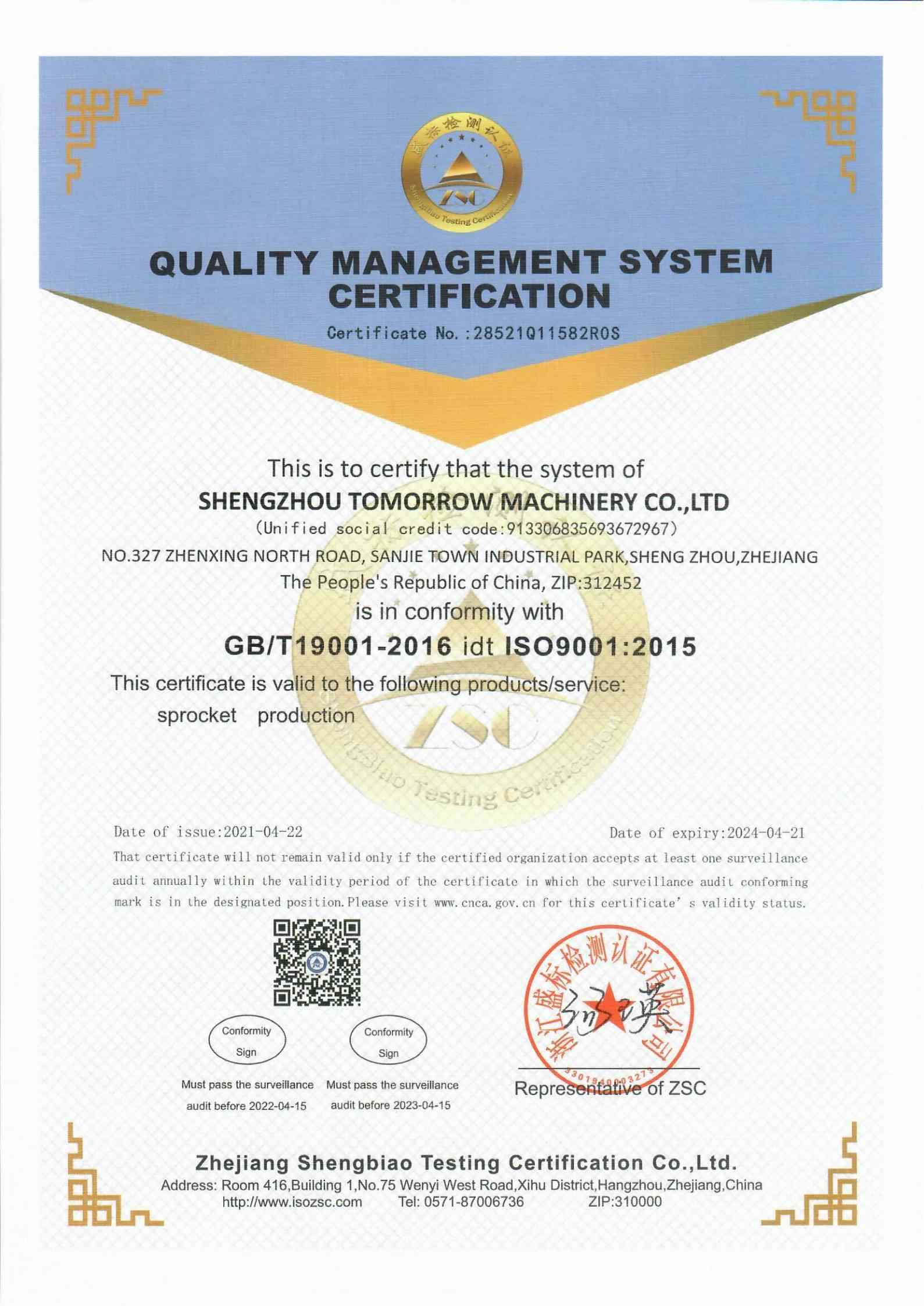

Industrial Sprockets Customer Support and Certifications

Top manufacturers leverage the latest CNC machining and digital design technologies. These innovations ensure consistent accuracy and reduce production errors, making the sprockets reliable for high-stress industrial environments

CTS® | Industrial Sprocket Manufacturer

CTS® is a professional industrial sprocket manufacturer with over 14 years in the power transmission industry. We have our own industrial sprocket factory and a professional technical team that can provide professional technical support and complete after-sales service.

As a professional industrial sprocket manufacturer with mature industrial sprocket manufacturing technical, we can not only produce standard industrial sprockets(ANSI/DIN/KANA) but also customize industrial sprockets according to your specific needs.

If you have any questions about industrial sprockets and other transmission parts, please contact us to help you.