Standard VS. Heavy-duty Roller Chain: Which Should You Choose?

- Share

- Issue Time

- Jul 31,2025

Summary

Comparison between standard and heavy-duty roller chains in strength, structure, and applications for industrial use.

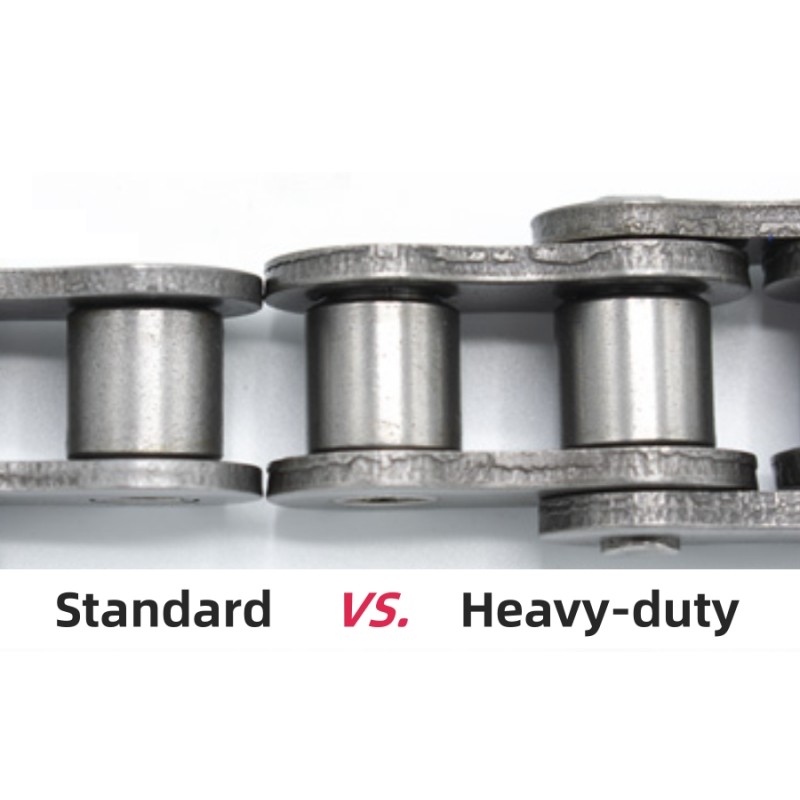

Selecting the right roller chain can make a significant difference in both performance and service life. Standard ANSI roller chains and Heavy-Duty (H-series) roller chains. While they might look similar, their construction, load capabilities, and applications vary greatly.

Standard Roller Chain

Standard roller chains follow the ANSI B29.1 standard and are the most common type for general industry. Made with standard-sized plates, pins, bushings, and rollers, they work well under steady loads, like in packaging machines, conveyors, and light equipment.

They are known for being simple, easy to find, and cost-effective. However, their thinner plates can be weak in situations with high shock or occasional heavy use.

Standard roller chains are widely used. However, in environments with high shock loads or intermittent heavy use, their thinner plates can become a point of weakness.

Heavy-duty Roller Chain

Heavy-duty roller chains (ANSI H-series) have the same pitch as standard chains. But they use thicker plates, larger pins, and sometimes stronger rollers. This robust design enables them to handle 15% to 30% more working load and resist fatigue more effectively than standard chains. They follow the ASME B29.28 standard for heavy-duty chains.

Because they are tougher, these chains work well in tough places like mining, forestry, and farm machines.

Standard VS. Heavy-duty Roller Chain

| ANSI Chain Size | Pitch(P) | Roller diameter(d1) | Pin diameter(d2) | Pin length(L) | Pin length(Lc) | Inner plate depth(h2) | Plate thickness(T) | Weight (per meter) |

19.05 | 11.91 | 5.94 | 25.90 | 27.70 | 18.00 | 2.42 | 1.50 | |

19.05 | 11.91 | 5.94 | 29.20 | 31.00 | 18.00 | 3.25 | 1.87 |

For example, while both #60 and #60H chains have a pitch of 19.05 mm, the side plate thickness in #60H is greater. This added material provides the chain with enhanced resistance to fatigue and stretching, particularly under fluctuating or impact-heavy loads.

Additionally, heavy-duty chains generally weigh more per meter and may slightly increase inertia in high-speed systems. However, this trade-off is often acceptable in exchange for much greater durability and longer operational life.

Chain Sprocket Compatibility

Both standard and heavy-duty chains can run on the same ANSI standard sprockets, as long as the pitch remains unchanged. This makes upgrading from a standard to a heavy-duty chain relatively straightforward without having to modify the sprocket configuration.

However, if you're moving to multi-strand heavy-duty chains (such as double or triple), the overall chain width may increase, requiring careful alignment and potentially wider sprockets.

When Should You Choose a Heavy-Duty Chain

If your system operates under shock loads, has start-stop cycles, or must function in abrasive or harsh outdoor conditions, a heavy-duty chain will deliver better fatigue resistance and longevity.

In contrast, if your application involves consistent speeds, lighter loads, or indoor environments, a standard chain is often sufficient and more economical.

While heavy-duty chains come at a higher upfront cost, they often last longer, reduce maintenance needs, and prevent unexpected failures, resulting in better total cost of ownership. Downtime can be far more expensive than the initial price difference between standard and heavy-duty options.

A food conveyor line with constant speed: Standard #40 chain.

A mobile asphalt mixer experiencing vibration and reversing torque: Heavy-duty #60H or #80H.

Roller Chain Types

CTS | Professional Roller Chain Supplier

As a trusted roller chain manufacturer, we're here to help you choose the best chain for your specific needs—and even customize it if needed.

We offer various industrial chain options: roller chains, conveyor chains, stainless steel chains, heavy-duty roller chains, double-pitch roller chains, roller chain attachments, etc.

If you want to replace your roller chains or have any questions about roller chains, please contact us.

FAQs

Are ANSI heavy-duty chains interchangeable with standard chains?

Yes, as long as the pitch is the same, they can typically run on the same sprockets. However, heavier chains may require tension adjustments or consideration for increased inertia.

How do I know if I need a heavy-duty chain?

If your system deals with shock loads, frequent starts/stops, or demanding environments, a heavy-duty chain will likely offer better performance and fewer breakdowns.