Roller Chain Sizing Chart: The Roller Chain Manufacturer's Expert Guide

- Share

- Issue Time

- Sep 3,2025

Summary

Master roller chain sizing with our comprehensive guide. As an experienced roller chain manufacturer, we explain how to measure, choose, and apply the right roller chains.

Why Proper Roller Chain Sizing Matters

Selecting the correct size minimizes wear, reduces elongation, and enhances energy efficiency—thus extending chain and machinery lifespan. Mismatched roller chains can cause misalignment, early failure, and increased downtime—costing time and money.

Roller Chain Size Chart Basics

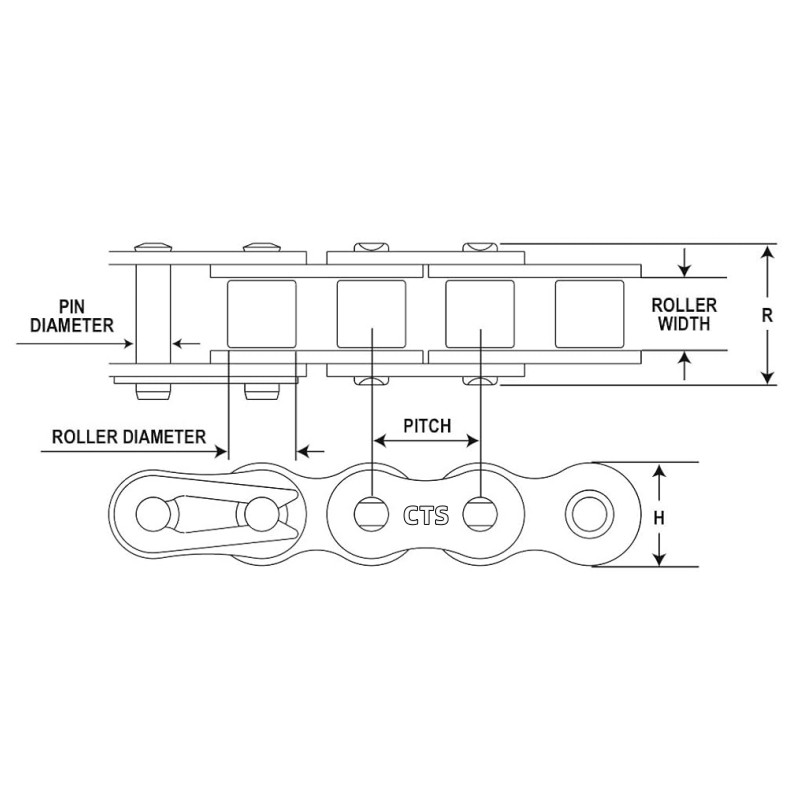

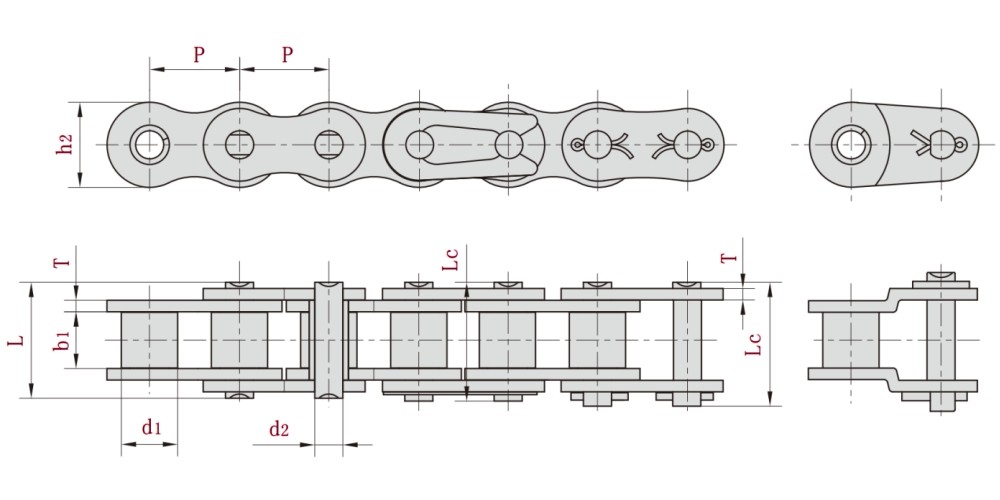

· Pitch: center-to-center distance between pins

· Roller diameter: ensures proper sprocket engagement

· Inner width: must match sprocket tooth width

· Pin diameter: affects shear strength and fatigue resistance

Reinforce using standards like ANSI and metric charts, referencing general industry charts

Step-by-step Guide: How to Measure Roller Chain

Using a digital caliper, ruler, and downloadable chain template for accurate measurements.

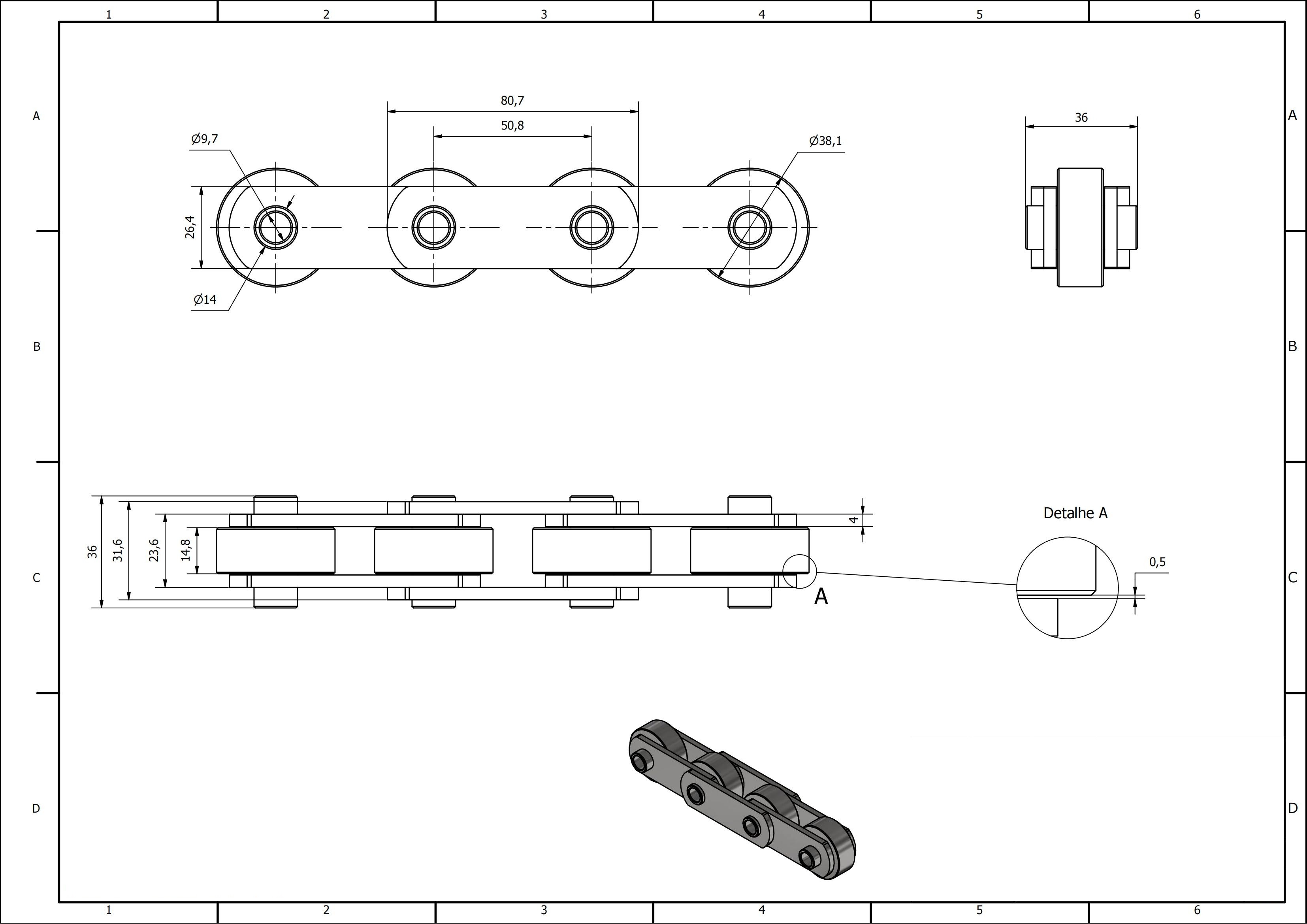

Measuring pitch (center-to-center of pins), roller size, and the inner plate width, then matching to standard charts like those in ANSI single-strand tables.

Next, match measurements to the standard roller chain size chart.

Roller Chain Sizing Chart Samples

ANSI Single-strand Roller Chain Size

Click to see more roller chain sizes, like multi-strand roller chains, which provide higher tensile strength and load capacity, suitable for heavy-duty machinery.

Insights from Our Manufacturer's Experience

Chain Plate Heating Treating

Our chain plates undergo advanced heat treatment processes to ensure optimal hardness and strength. By carefully controlling temperature and cooling cycles, we enhance the plate's wear resistance, fatigue strength, and durability, allowing the roller chain to withstand high loads and extended operating hours without premature failure.

Chain quality testing

Every roller chain is rigorously tested before it leaves our factory. We conduct dimensional checks, tensile strength tests, fatigue tests, and surface inspections to guarantee that each chain meets or exceeds ANSI/ISO standards. Our strict quality control ensures consistent performance, safety, and reliability in demanding industrial environments.

Custom Specialty Chains

We offer customized roller chain solutions designed to meet unique application needs. Options include corrosion-resistant materials, specialty coatings, extended pitch designs, heavy-duty configurations, and chains for extreme temperatures or harsh environments. Our engineering team works closely with customers to deliver precise, application-specific solutions.

When standard roller chains do not meet unique operational applications, contact our factory specialists to give you custom solutions.

Trust & Expertise: About CTS-ChinaTransmissionS

High-tensile & Wear-resistant Roller Chain

✔ ISO Certificated Roller Chain

✔ High-performance Material✔ Nitro-Carburizing Compound Heat Treating

✔ Wide-waist Link Plates

Contact us for more roller chain details.

Durable Roller Chain Selection

ANSI Roller Chain

Metric Roller Chain

Heavy-duty Roller Chain

Stainless Steel Roller Chain