Parts of Roller Chains | Structure, Function & Manufacturing

- Share

- Issue Time

- Sep 12,2025

Summary

Learn the key parts of roller chains, their functions, and the manufacturing process. CTS offers expert insights and quality roller chain solutions.

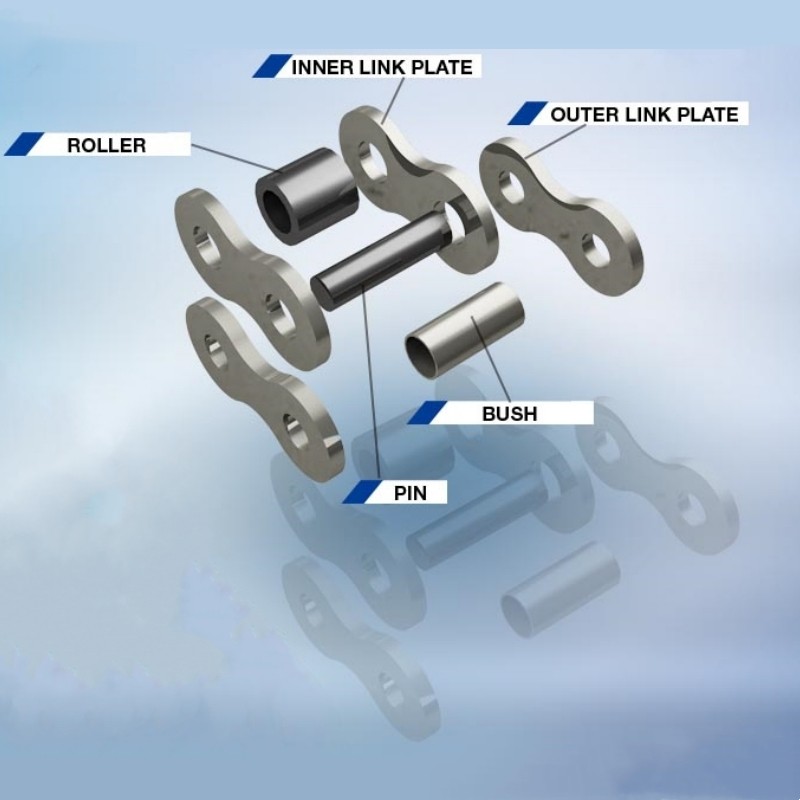

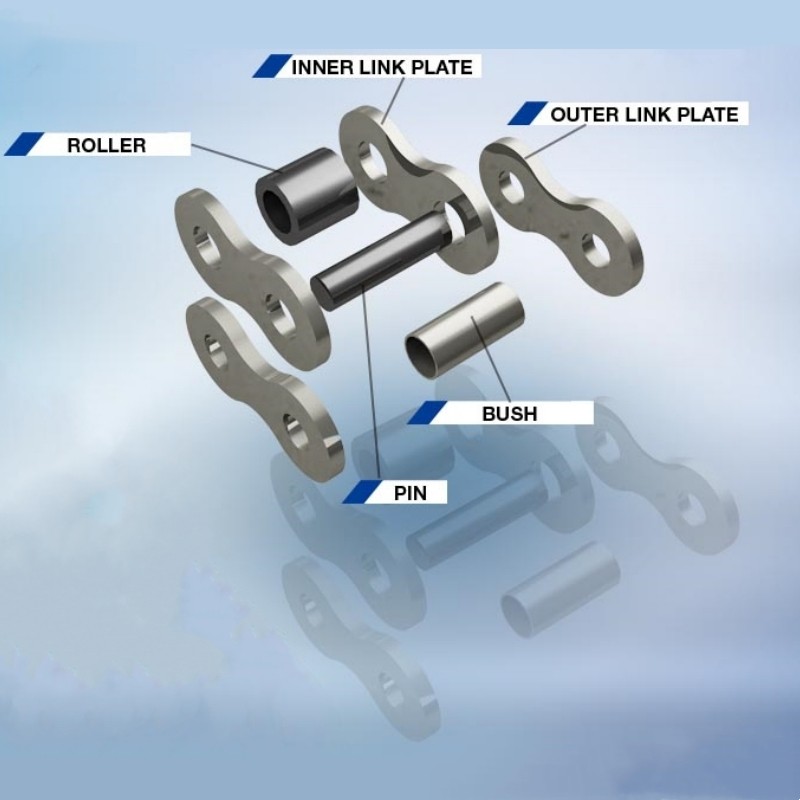

Basic Structure of Roller Chains

A roller chain is a series of interconnected parts that work together to transmit motion and power. It may look simple, but each component is carefully engineered to achieve durability and efficiency.

Key components include:

• Chain Plates

• Pins

• Bushings

• Rollers

• Connecting Links

• Optional seals or attachments

How These Parts Work Together

When the roller chain engages with the sprocket, the rollers rotate around the bushings, while the pins pivot inside the bushings. This design reduces friction and distributes the load evenly across all parts.

How Roller Chain Parts Are Manufactured

One of the reasons roller chains perform so well is the highly controlled manufacturing process behind each part. At CTS, every component goes through rigorous production steps to ensure strength, accuracy, and durability.

Chain Plates(Inner and Outer)

·Process: High-strength steel sheets→Stamping→Heat treatment→Surface treatment

·Purpose: Achieve high tensile strength and fatigue resistance.

Chain Pins

·Process: Cutting→Precision turning→Heat treatment→Grinding

·Purpose: Ensure smooth rotation and high resistance to wear and shear.

Chain Bushings

·Process: Machining from seamless steel→Heat treatment→Surface hardening

·Purpose: Provide a low-friction bearing surface for the pins and rollers.

Chain Rollers

·Process:Cold extrusion →Heat treatment→Surface polishing

·Purpose: Reduce friction with sprockets and withstand repeated impacts.

Final Roller Chain Assembly

·All components are assembled with high precision.

·Chains undergo performance testing, lubrication, and quality inspection before delivery.

Why Understand Roller Chain Parts Matters

Knowing the parts of a roller chain provides several benefits:

Maintenance: Identify worn parts(like rollers or pins)before failure.

Replacement: Order the correct spare parts with proper terminology.

Selection: Choose the right chain size and type for your equipment.

For engineers, technicians, and buyers, this knowledge can save time, money, and downtime.

CTS® | Expertise as a Roller Chain Manufacturer

At CTS-ChinaTransmissionS, we specialize in designing, producing, and supplying high-quality roller chains for global customers.

✔ Advanced heat treatment and machining technology.

✔ In-house testing for tensile strength and fatigue resistance.

✔ Custom solutions for agriculture, conveyors, and heavy industry.

If you have any questions, please feel free to contact us.

CTS® professional technicians will be happy to help you!

FAQs

Which parts wear out the fastest?

Typically, rollers and bushings wear first due to friction with sprockets.

Can individual roller chain parts be replaced?

Yes, connecting links and some parts can be replaced, but in most cases, it is better to replace the entire chain.

How does manufacturing affect chain quality?

Precision machining, heat treatment, and surface finishing are critical. Poorly made parts will reduce strength and shorten service life.