Metric Roller Chain Size Chart | Dimension Guide

- Share

- Issue Time

- Nov 3,2025

Summary

Know the metric roller chain size chart with detailed dimensions, and the difference from ANSI roller chains. Select the right metric roller chain for your machinery and application.

If you work with industrial machinery from Europe or other regions outside North America, you've likely encountered the metric roller chain system. While our previous guide covered ANSI roller chain sizes, understanding metric chains is crucial for maintaining and sourcing parts for international equipment.

What Is Metric Roller Chain

Metric roller chains are manufactured to ISO (International Organization for Standardization) standards, with all their dimensions measured in millimeters. They are commonly used in European-made machinery, agricultural equipment, and various industrial applications worldwide. The most significant visual difference is their straightforward numbering system, which directly relates to the chain's pitch.

Metric Roller Chain Size

The numbering system for metric chains is remarkably intuitive.

For example: Chain No. 08B.

The first number (08) represents the chain's pitch in millimeters, divided by 1.6. So, 08 x 1.6 = 12.7 mm. This is the distance between the centers of two adjacent pins.

The letter (B) indicates the series or type of chain. In this case, 'B' refers to a standard series. You may also encounter other letters for different applications, but 'B' is the most common for general power transmission.

Another example: Chain No. 16B.

16 x 1.6 = 25.4 mm pitch.

This simple formula allows you to instantly know the chain pitch of any standard metric chain just by looking at its number.

Metric Roller Chain Size Chart

Note: Roller chain dimensions are nominal and may vary slightly by manufacturer. Always consult technical datasheets for critical applications.

Key Roller Chain Dimensions Explained

Roller Chain Pitch

This is the most fundamental chain dimension. It's the distance between the centers of two adjacent link pins. It determines the size of the sprocket teeth and the basic "length" of the chain.

Chain Roller Diameter

This is the maximum outside diameter of the roller. It must fit smoothly between the sprocket's teeth for proper engagement and minimal wear.

Inner Width

This is the minimum distance between the inner link plates. It determines the thickness of the sprocket teeth and the maximum width of any attachments.

Metric vs. ANSI Roller Chain: The Difference?

While they serve the same purpose, mixing up ANSI and Metric roller chains can lead to machine failure. Here's a quick comparison:

| Standard | ISO 606 | ASME B29.1 |

Measurement Unit | Millimeters | Inches |

Numbering System | Based on formula (e.g., 08 =12.7 mm pitch | Coded number (e.g., #40 =0.5" pitch) |

Interchangeability | Not Directly Interchangeable. Even if the chain pitch is similar, the roller diameter and inner width differ. | |

Application Regions | North America, Japan, parts of Asia | Europe, parts of Asia |

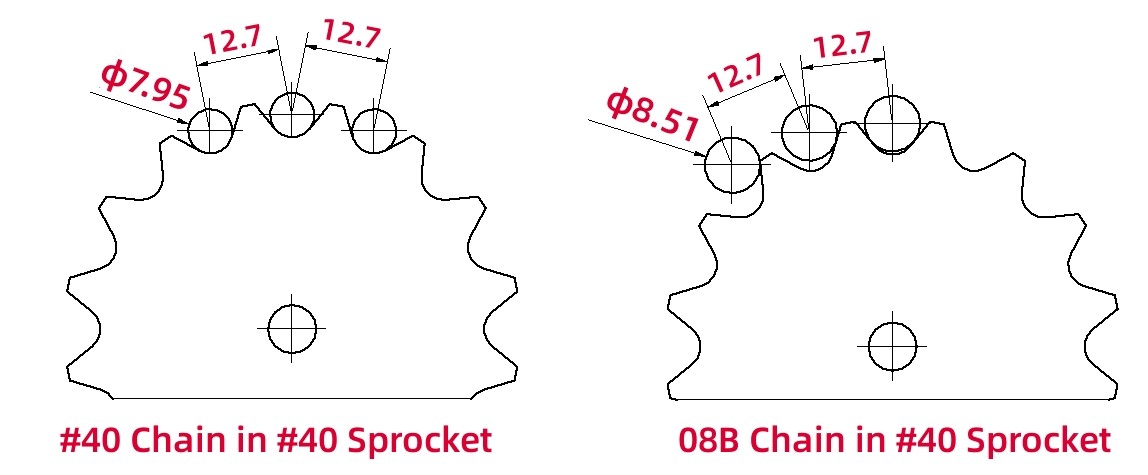

A metric 08B chain and an ANSI #40 chain both have a 12.7mm (0.5 inch) pitch. However, their roller diameters and inner widths are different. This mismatch will cause rapid wear and may lead to chain breakage.

How to Choose the Right Metric Roller Chain?

1) Identify the Existing Chain: The best way is to check the number stamped on the chain link plates (e.g., 08B, 16B).

2) Measure the Pitch: If the number is worn off, measure the distance between three consecutive pins and divide by two to get the pitch in mm. Then, use the formula (Chain Number = Pitch / 1.6) to find the likely chain number.

3) Match the Sprocket: The chain and sprocket must match. Always use a sprocket that is specifically designed for your metric chain size (e.g., an 08B sprocket for an 08B chain).

4) Consider Application Loads: Check the chain's breaking strength in the chart. Then, choose a chain that is much stronger than your expected load to ensure a safe margin for your machine's operating conditions.

Ready to Order the Perfect Metric Roller Chain?

As a leading global supplier, CTS-ChinaTransmissions manufactures and stocks a complete range of high-quality ISO metric roller chains, covering all standard roller chain sizes from compact 04B to 72B.

If you need any help, please contact us for technical support and competitive quotations.

FAQs

Is an 08B chain the same as a #40 chain?

No. While they share the same pitch (12.7mm), their roller diameter and inner width are different. They are not interchangeable.

Can I use a metric chain on an ANSI sprocket?

It is strongly discouraged. The mismatch in roller diameter and inner width will cause improper meshing, leading to excessive noise, rapid wear on both the chain and sprocket, and a high risk of premature failure.

How do I know if my chain is metric or ANSI?

Check the number stamped on the link plates. If it's a number followed by a 'B' (e.g., 10B, 16B), it's metric. If it's a number with a '#' prefix or no letter (e.g., #50, 60), it's likely ANSI. Measuring the pitch in millimeters and comparing it to the charts can also help confirm.