Manure Spreader Chain Guide

- Share

- Issue Time

- Dec 3,2024

Summary

This guide will help you understand, choose, and maintain manure spreader chains.

Manure spreader chains are indispensable for maintaining soil health and streamlining waste management. This guide will help you understand, choose, and maintain manure spreader chains.

What Is Manure Spreader Chain

Manure spreader chains are specialized chains used in agricultural machinery that distribute manure evenly across fields. These chains power the conveyor mechanism within manure spreaders, ensuring smooth and consistent spreading of organic material. Their design allows them to handle heavy loads while operating efficiently in harsh outdoor conditions.

Manure spreader chains are critical for improving soil fertility and structure. By evenly distributing manure, these chains help farmers optimize crop yield, reduce chemical fertilizer dependency, and maintain sustainable agricultural practices. Their reliability directly impacts the effectiveness of waste recycling in farming.

Types Of Manure Spreader Chain

There are four different styles of chain that you may have on your manure spreader which are Steel Detachable Chain, Pintle Chain, T-Bar Chain, and T-Rod Chain.

Steel Detachable Chain

Steel Detachable Chain is characterized by its lightweight design and ease of use. Made from heat-treated steel, its detachable links make it easy to repair or assemble, reducing downtime in operations. It offers versatility and is compatible with various agricultural machines, particularly in light to medium-duty applications. Farmers who prioritize regular maintenance and need an economical solution for smaller manure spreaders find this chain a reliable option.

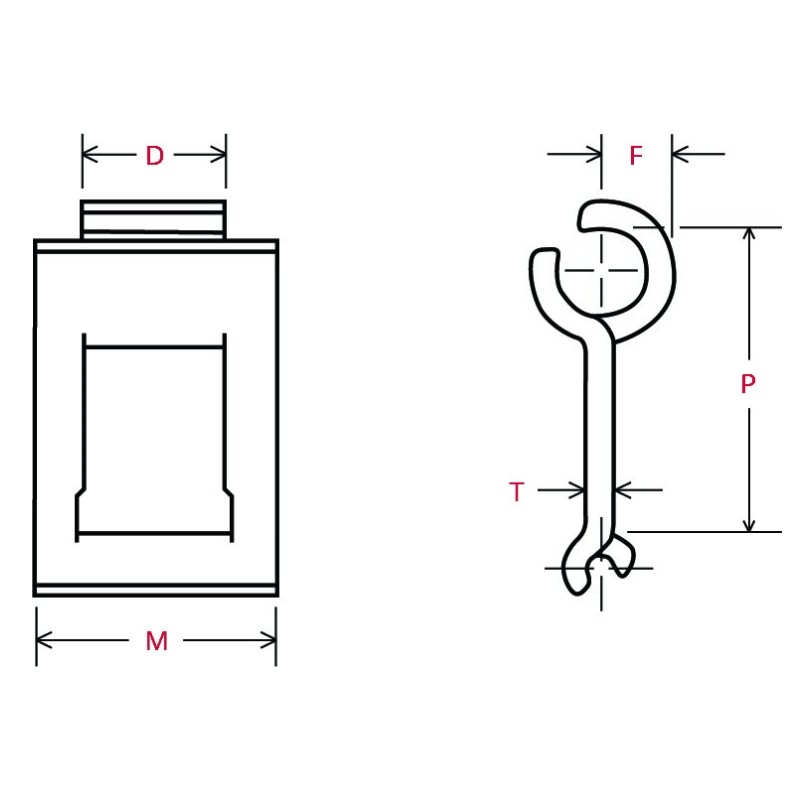

Pintle Chain

Pintle Chains are robust in construction and flexibility. Featuring open barrel links, pintle chains are specifically designed to prevent material buildup, which is a common challenge in manure handling. This design not only ensures smoother operation but also makes cleaning and maintenance significantly easier. Pintle chains are highly durable, often made with heat-treated alloys, and are well-suited for handling heavy loads. They perform exceptionally well in large-scale agricultural operations, especially when dealing with abrasive materials such as sand or grit mixed with manure.

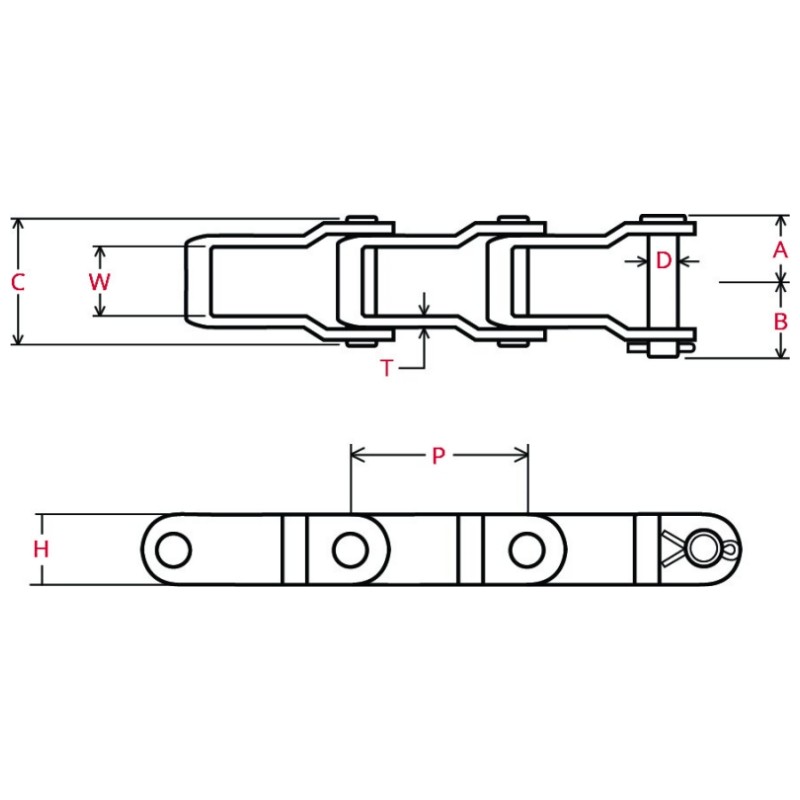

T-Bar Chain

The T-Bar Chain is engineered for heavy-duty applications, featuring T-shaped crossbars welded onto the chain links. This unique design provides exceptional stability and strength, ensuring consistent performance even under high tensile loads. One of the key benefits of the T-Bar Chain is its long lifespan, thanks to its resistance to wear and breakage. It excels in large-scale farming environments where high-capacity manure spreaders are required to manage heavy, wet, or dense manure. The T-bar design minimizes slippage and ensures even manure distribution, making it indispensable for farmers looking to maximize efficiency in intensive farming operations.

T-Rod Chain

The T-Rod Chain combines flexibility and strength, making it a versatile choice for medium to heavy-duty manure spreaders. Constructed with horizontal rods as the core component, these chains resist bending or deformation, even under substantial loads. Their smooth operation ensures consistent performance across a range of manure consistencies, from liquid to semi-solid. T-Rod Chains are highly customizable, available in various sizes and configurations to suit specific machinery. This adaptability, paired with their robust design, makes them a preferred choice for farmers working in diverse conditions, including challenging terrains where flexibility without compromising strength is essential.

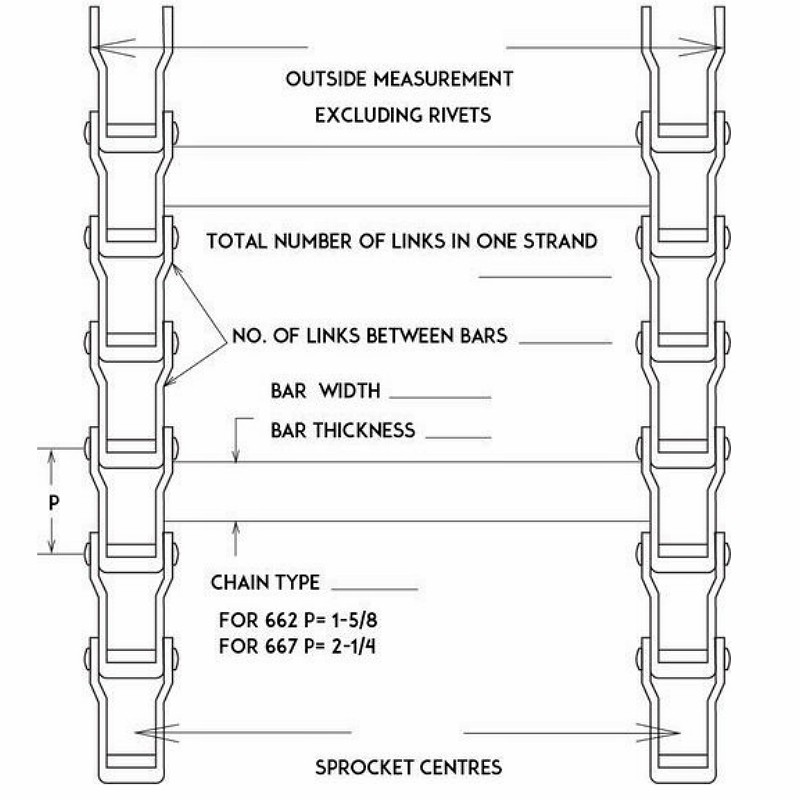

How To Size Manure Spreader Chain

To figure out what size and spreader configuration please use the above diagram. If you happen to know the make and model contact us today for a quote.

Features of High-Quality Manure Spreader Chains

Material Strength and Durability

Manure spreader chains are made from high-grade steel or alloy materials are more resistant to wear and can handle larger loads effectively.

Corrosion Resistance

High-quality manure spreader chains often feature coatings or treatments, such as galvanization, to protect against rust and corrosion.

Smooth Operation for Consistent Spreading

Precision in manufacturing ensures that the manure spreader chain moves smoothly within the spreader, reducing downtime and maintenance needs.

Choosing the Right Chain for Your Spreader

Evaluating Your Operational Needs

Consider the volume of manure your spreader handles and the frequency of use. This helps in selecting a chain that meets your workload requirements.

Matching Chains to Equipment Requirements

Review the manufacturer’s specifications for your manure spreader to ensure compatibility with chain types, sizes, and configurations.

CTS® | Reliable Transmission Chain Supplier

CTS® Manure Spreader Chain

We can supply manure spreader chain replacement by these brands and OEM replacements with attachments assembled onto them.

CTS®-ChinaTransmissionS is a professional transmission chain supplier in the power transmission industry. As an experienced manure spreader chain supplier, we manufacture tested and certified chains, ensuring reliability and high performance. Besides, we can also provide customized manure spread chains for your spreaders.

We offer a wide range of transmission chain options: drop forged rivet-less chains, welded steel chains, 81X lumber conveyor chains, roller chains, conveyor chains, heavy-duty roller chains, etc.

If you have any questions about industrial transmission chains, please contact us to help you.

FAQs

What are the signs that my manure spreader chain needs replacing?

Look for stretched links, visible cracks, or irregular operation. Unusual noises during use can also indicate chain issues.

What materials are best for high-performance manure spreader chains?

Manure spreader chains made of high-grade steel with corrosion-resistant coatings, such as galvanized or stainless finishes, are ideal for durability and performance.