Industrial Sprockets: Complete Selection Guide

- Share

- Issue Time

- May 13,2025

Summary

Industrial sprockets ensure efficient power transmission; choosing the right one boosts performance and equipment longevity.

Industrial Sprockets

Industrial sprockets are toothed wheels designed to engage with roller chains, facilitating the transmission of rotary motion between shafts. Unlike gears, which mesh directly with other gears, sprockets interact with chains.

Teeth: Engage with the chain links.

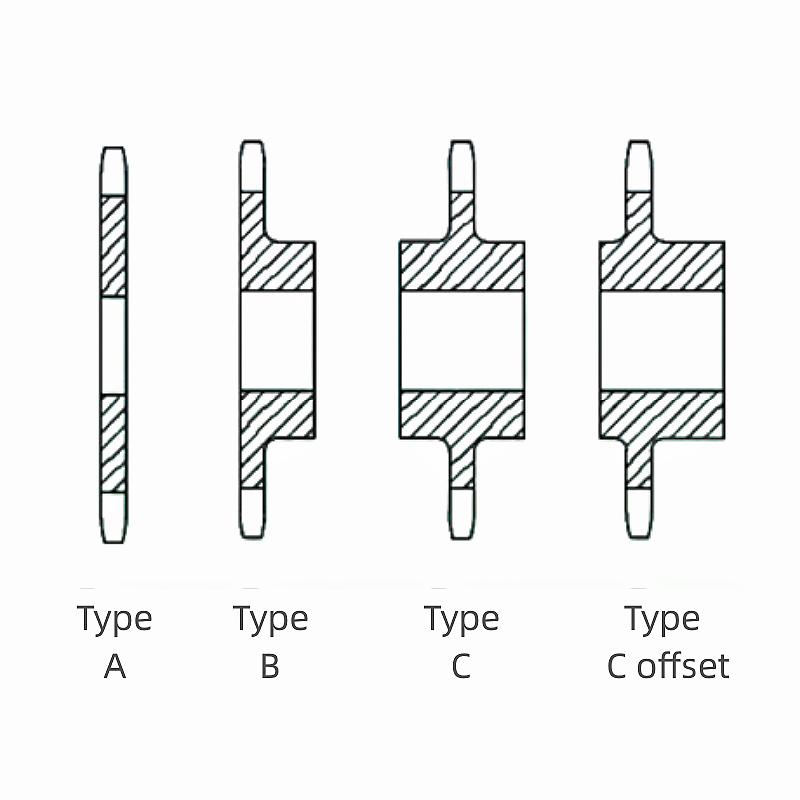

Hub: Central part of the sprocket, which may vary in design (A, B, or C type).

Bore: The central hole through which the sprocket is mounted onto a shaft.

Types of Industrial Sprockets

ANSI (American National Standards Institute) standard sprockets are designed to comply with ANSI B29.1 specifications, ensuring compatibility with standard roller chains.

ISO and DIN sprockets adhere to international standards such as ISO 606 and DIN 8187, making them suitable for global applications. They are often used in European-designed equipment.

Double pitch sprockets are designed for use with double pitch roller chains. They are commonly found in conveyor systems, packaging machinery, and material handling equipment, where they help reduce weight and cost.

Taper-lock Sprockets

Taper-lock sprockets with the tapered bushing are easy to install and remove.

Idler Sprockets

Idler sprockets are non-driven sprockets used to guide or take up slack in a chain drive system.

Customized / OEM Sprockets

Unique sprocket bore sizes for specialized shafts, special tooth profiles for unique chain designs, and OEM replacements for legacy or specialized machinery.

How To Select Sprocket

Chain Compatibility: Ensure the sprocket matches the chain's pitch and size.

Number of Teeth: Affects the speed ratio and torque transmission.

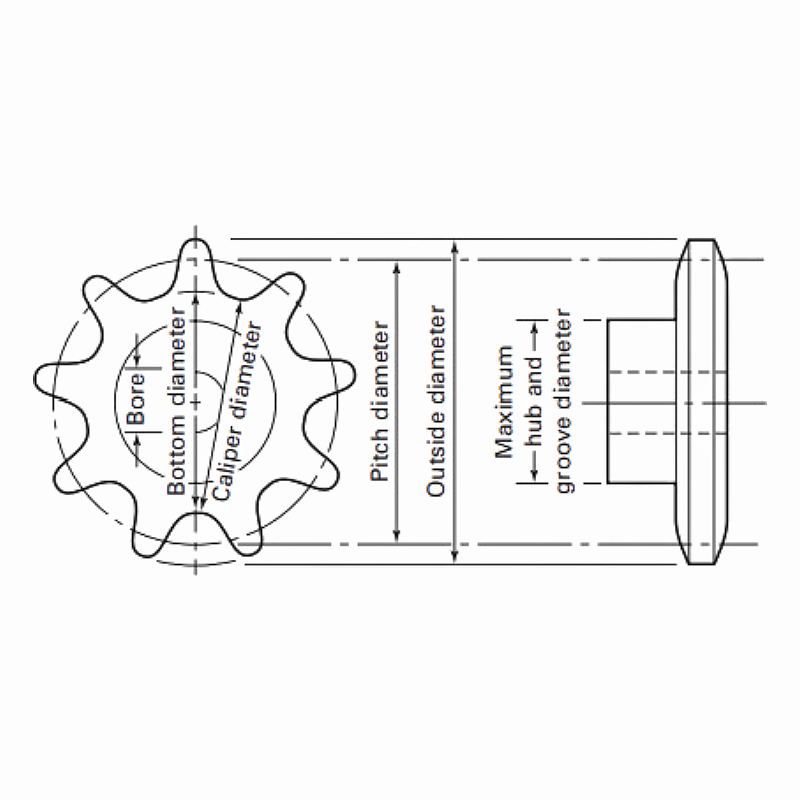

Pitch Diameter: The diameter of the circle formed by the centers of the chain pins as they engage with the sprocket.

Hub Type: Determines the mounting configuration (A, B, or C style).

Bore Type: Options include plain bore, finished bore, or taper bore.

Material Selection: Common materials include carbon steel and stainless steel, chosen based on the application's environmental conditions.

Surface Treatment: Treatments like black oxide or zinc plating enhance corrosion resistance.

Application Environment: Consider factors like exposure to moisture, chemicals, or extreme temperatures.

Carbon Steel Industrial Sprockets

Stainless Steel Industrial Sprockets

How to Measure and Identify a Sprocket

1) Determine the Chain Pitch: Measure the distance between the centers of two consecutive chain pins.

2) Count the Number of Teeth: Essential for calculating speed ratios.

3) Measure the Bore Diameter: Ensures proper fit onto the shaft.

4) Identify the Hub Types: Affects mounting and alignment.

5) Note the Material and Surface Treatment: Important for environmental compatibility.

Matching Sprockets with Roller Chains

Proper alignment between sprockets and chains is vital:

Chain Pitch and Sprocket Compatibility: Mismatched pitches can lead to premature wear.

Single vs. Multi-Strand Sprockets: Multi-strand sprockets are used for higher load applications.

Chain Tension and Alignment: Proper tension prevents slippage and reduces wear.

Need help finding the right sprocket for your application? Contact our team for expert guidance and tailored solutions.

Choose CTS® Sprocket

As a professional industrial sprocket manufacturer, CTS-ChinaTransmissionS offers a comprehensive range of high-quality sprockets. We have standard stock products, our clients worldwide. Combining advanced machinery with skilled technicians, we can provide custom solutions to meet unique client needs.

If you have any questions about industrial chains and sprockets, please contact us for help.