How To Choose The Right Industrial Transmission Chain For Your Application

- Share

- Issue Time

- Oct 14,2024

Summary

This guide will help you how to choose the right industrial chains for your needs.

Selecting the appropriate chain ensures longevity, efficiency, and safety. Transmission chains are used across numerous industries, from food processing to construction, each requiring specific durability and strength characteristics.

Type Of Industrial Transmission Chains

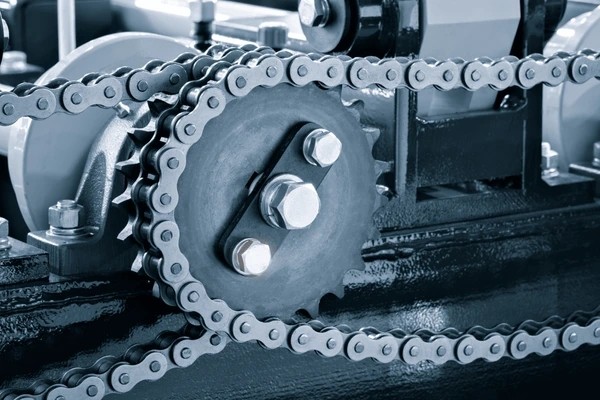

Widely used for power transmission in various machinery, from conveyors to automotive equipment. Their cylindrical rollers reduce friction and enhance durability.

Essential in moving products and materials, commonly found in industries like food processing and packaging. They handle high loads and come in different configurations, such as flat-top and side-flexing designs.

Heavily used in lifting equipment, offering excellent tensile strength, especially in forklifts and cranes.

Specialty Chains

These include stainless steel or corrosion-resistant chains, used in specific environments such as food or medical industries where hygiene and durability are critical.

Industrial Chain Durability

The material composition plays a significant role in the chain’s durability. For example, stainless steel chains are highly resistant to corrosion, making them ideal for environments with moisture or chemicals, such as food processing plants. In contrast, standard steel chains are used in less corrosive environments but may require more frequent lubrication to maintain longevity.

Environmental factors, such as temperature and exposure to harsh chemicals, should also influence your choice. Industrial chains exposed to high temperatures or abrasive environments need to be heat-treated or specially coated for extra durability.

Industrial Chain Strength

Industrial chains differ in their ability to handle loads:

Load Capacity: Industrial chains like leaf chains are designed to withstand heavy tensile forces, making them suitable for high-stress applications, such as cranes or mining machinery.

Chain Design: Roller chains are efficient for transmitting power, but leaf chains excel in lifting applications due to their higher tensile strength. The shape and design of the links can affect both the strength and flexibility of the chain in various operations.

For high-load applications, such as material handling in construction, the chain's tensile strength must align with the machinery's requirements.

Industrial Chain Application

✔ Food Processing:

Stainless steel chains are essential here to ensure hygiene and corrosion resistance.

✔ Heavy Industry:

For mining or construction, industrial chains that withstand high tensile loads and abrasive conditions.

✔ Packaging:

Conveyor chains are key in this sector, with the need for continuous movement and precise control.

Environmental considerations, such as moisture or chemical exposure, are critical in choosing a chain that will last and perform well under specific conditions.

Choosing The Best Industrial Chain For Your Needs

To ensure you make the best decision, ask:

• What’s the load capacity required?

• What environmental factors, such as temperature or moisture, will the chain face?

• How often will the chain need maintenance?

It’s always advisable to consult with experts or manufacturers who can help you assess the exact requirements of your application, ensuring both performance and safety are prioritized.

CTS-ChinaTransmissionS is a professional roller chain manufacturer, any questions let us know, Contact us, and our technicians will be happy to help you!