Drop Forged Rivetless Chains

- Share

- Issue Time

- Dec 18,2024

Summary

This guide will talk about Drop Forged Rivetless Chains, make you know more about drop-forged chains, and help you choose the right chain.

Drop Forged Rivetless Chain

Drop Forged Rivetless Chains are specialized industrial chains made using the drop forging process. Unlike traditional chains, they are constructed without rivets, offering a seamless, sturdy design that enhances durability and performance.

Drop forging involves shaping metal under high pressure, creating a uniform grain structure that enhances the material's strength and resilience. For rivetless chains, this method ensures that each link is free of weak points typically associated with welded or riveted joints.

Drop Forged Rivetless Chain Type

Standard Series Drop Forged Rivetless Chain

468/698/998/9118

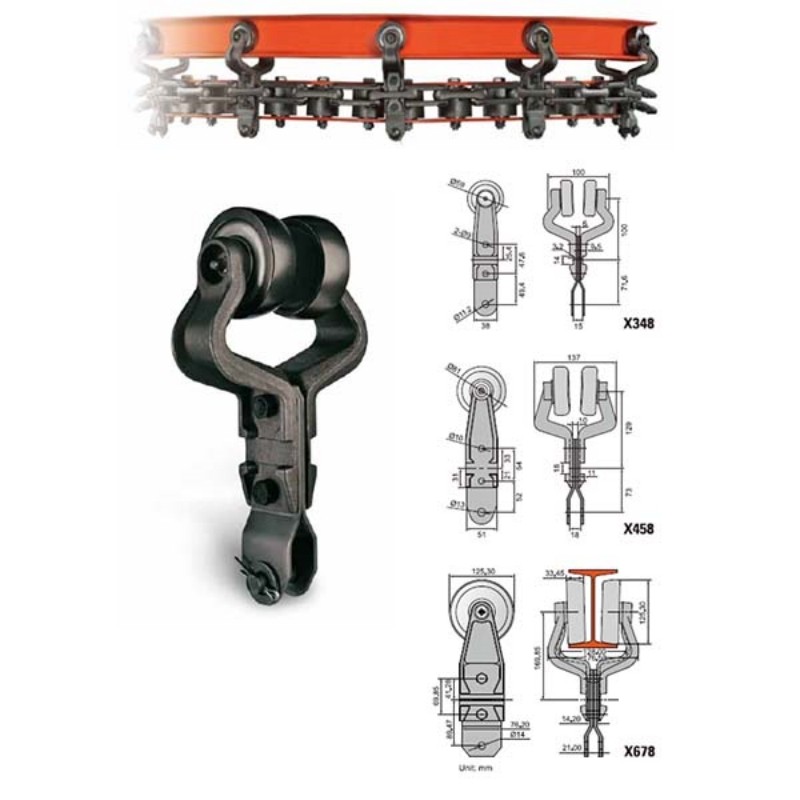

X-Type Drop Forged Rivetless Chain

X228/X348/X458/X658/X678

S-Type Drop Forged Rivetless Chain

S348/S458/S468

Materials Used in Drop-Forged Rivetless Chains

The performance of a Drop Forged Rivetless Chain largely depends on the material used. Manufacturers typically opt for premium alloy steels due to their excellent balance of strength, wear resistance, and toughness.

Alloy Steel for Strength and Wear Resistance

Alloy steel links are known for their ability to withstand high loads and harsh environments. Their wear resistance ensures the chain maintains its integrity even under continuous operation in abrasive conditions.

Heat-Treated Variants for Longevity

Heat treatment processes, such as quenching and tempering, further improve the mechanical properties of these chains, increasing their lifespan and reducing the need for frequent replacements.

Drop Forged Rivet-less Chains and Sprockets

As a professional chain and sprocket manufacturer, CTS® not only has drop forged rivetless chain but also manufactures drop forged rivetless chain sprockets that match them. If you have any needs, please contact us and our technicians are happy to help you.

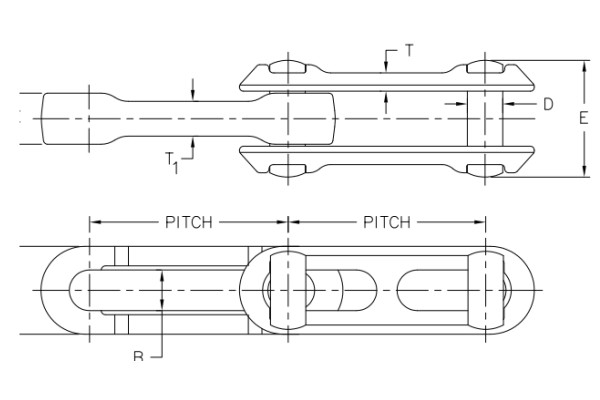

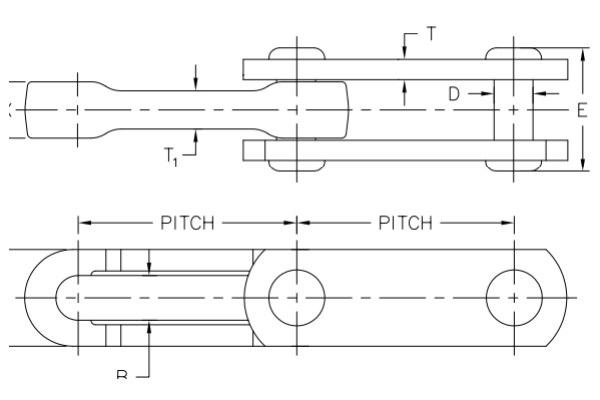

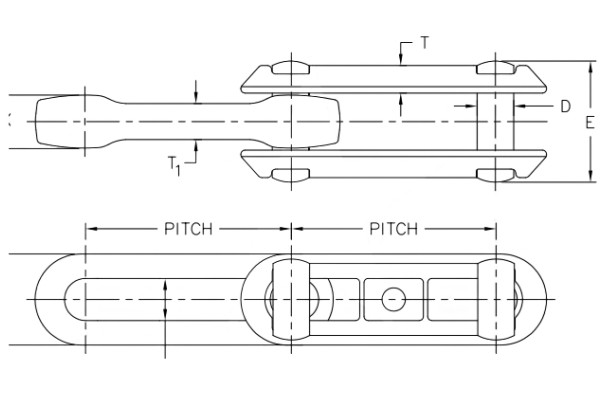

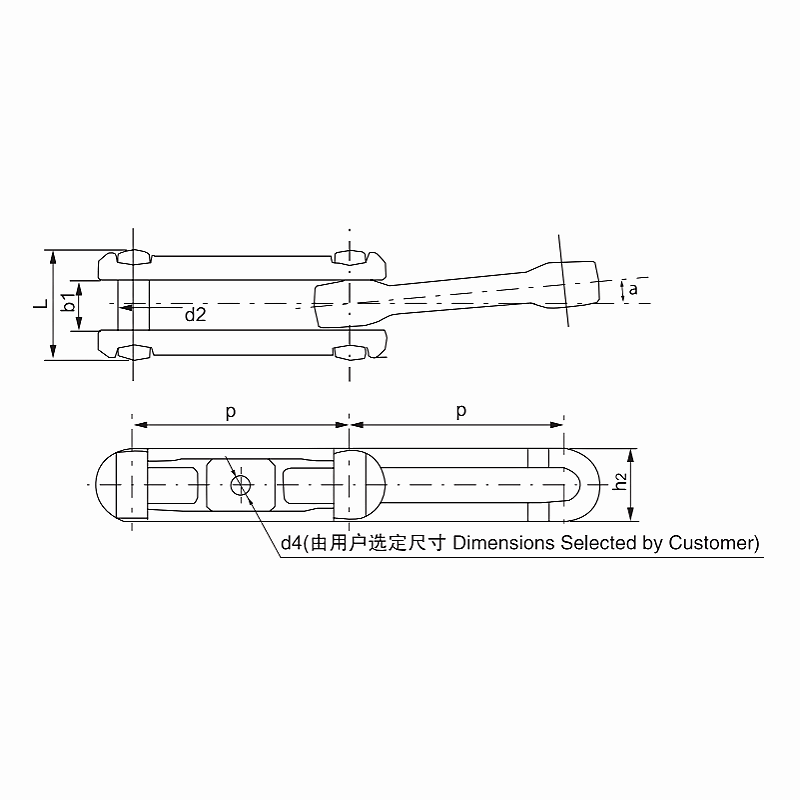

Drop Forged Rivetless Chain Dimension | X-type

Drop Forged Rivetless Chain Trolley

Trolleys are equipped with wheels or rollers that allow smooth travel along the chain system. The wheels are usually made from durable materials such as steel, nylon, or other high-strength polymers to reduce wear and improve the system's longevity.

Depending on the specific application, trolleys may have customized attachments such as hooks, platforms, or carriages to hold and transport particular types of goods.

Applications of Drop Forged Rivetless Chains

Overhead Applications in Manufacturing

In overhead conveyor systems, drop forged rivetless chains' lightweight design minimizes the strain on equipment, ensuring efficient operation.

Floor-Based Material Handling Systems

On the ground, drop-forged rivetless chains are commonly used for moving bulk materials in a controlled and consistent manner.

Choose CTS® Drop Forged Rivetless Chain

✔ Efficiency

Our high-quality palm oil chains improve efficiency, less downtime, and smoother operations.

✔ Durability

Manufactured from hardened steel, our palm oil chains are durable and require fewer replacements.

CTS®-ChinaTransmissionS is a professional agricultural chain manufacturer in the power transmission industry. As an experienced agricultural chain supplier, we manufacture Drop Forged Rivetless Chains with high-quality steel material. Besides standard agricultural chains, we can also provide customized agricultural chains for your application.

We offer a wide range of industrial transmission chain options: drop forged rivet-less chains, welded steel chains, 81X lumber conveyor chains, roller chains, conveyor chains, heavy-duty roller chains, etc.

If you have any questions about industrial transmission chains, please contact us to help you.

Professional Chain Manufacturers

With years of experience, we understand the needs of your application.

Various chain attachments

Attachments are commonly used for agricultural roller chains, we can supply complete chain attachment options.

High Standards of Quality Control

Our rigorous quality checks ensure every chain meets the highest standards.