ANSI Roller Chain Sprocket

- Share

- Issue Time

- Sep 16,2025

Summary

ANSI roller chain sprocket: types, materials, standards, and applications. Learn how to choose the right sprocket for your equipment with CTS.

Roller chain sprockets are essential components in power transmission and conveyor systems, playing a crucial role in the efficient and reliable operation of various machinery.

Our ANSI sprockets are made from durable materials such as steel and stainless steel to withstand a wide range of operating conditions. Manufactured strictly to ANSI standards, our ANSI chain sprockets are interchangeable with different manufacturers' sprockets.

ANSI Roller Chain Sprocket by Chain Size

Types of ANSI Roller Chain Sprocket

Chain Sprocket Number of Rows

For different numbers of rows of sprockets, there are simplex chain sprockets, duplex chain sprockets, triplex chain sprockets, and multi-strand chain sprockets.

1) Simplex sprockets are designed for single-strand chains and are suitable for light to medium-duty applications.

2) Duplex sprockets are compatible with double-strand roller chains, providing higher load capacity and strength.

3) Triplex and multiplex sprockets are designed for heavy-duty applications that require transmitting high torque and power.

Simplex Chain Sprockets

Duplex Chain Sprockets

Triplex Chain Sprockets

Chain Sprocket Material

For different materials of ANSI roller chain sprockets:

• Carbon Steel-Durable and economical,widely used for general industrial applications.

· Stainless Steel-Corrosion-resistant,suitable for food,pharmaceutical,and chemical industries.

· Cast Iron-Strong and cost-effective,often used in heavy machinery.

Carbon Steel Industrial Sprockets

Stainless Steel Industrial Sprockets

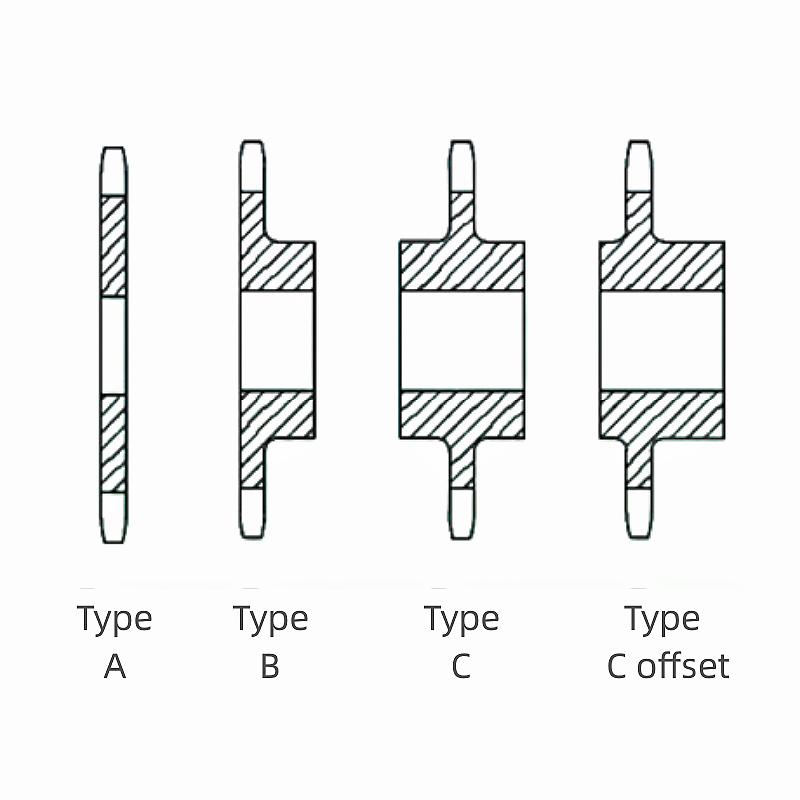

Chain Sprocket Hub

ANSI roller chain sprockets are available in various configurations to meet different application needs. For different sprocket hub types, there are A hub sprocket, B hub sprocket, C hub sprocket, and D hub sprocket.

Type A sprockets consist solely of a plate with no added thickness or hubs.

Type B sprockets feature a hub on one side.

Type C sprockets have hubs of equal thickness on both sides of the plate.

Type C offset or Type D sprockets also have two hubs, but each hub has a different thickness, resulting in an asymmetrical sprocket.

Chain Sprocket Bore

For different chain sprocket bore types, there are plain bore/pilot bore sprockets, finished bore sprockets and taper bore sprockets.

Plain Bore Sprockets

Finished Bore Sprockets

Taper Bore Sprockets

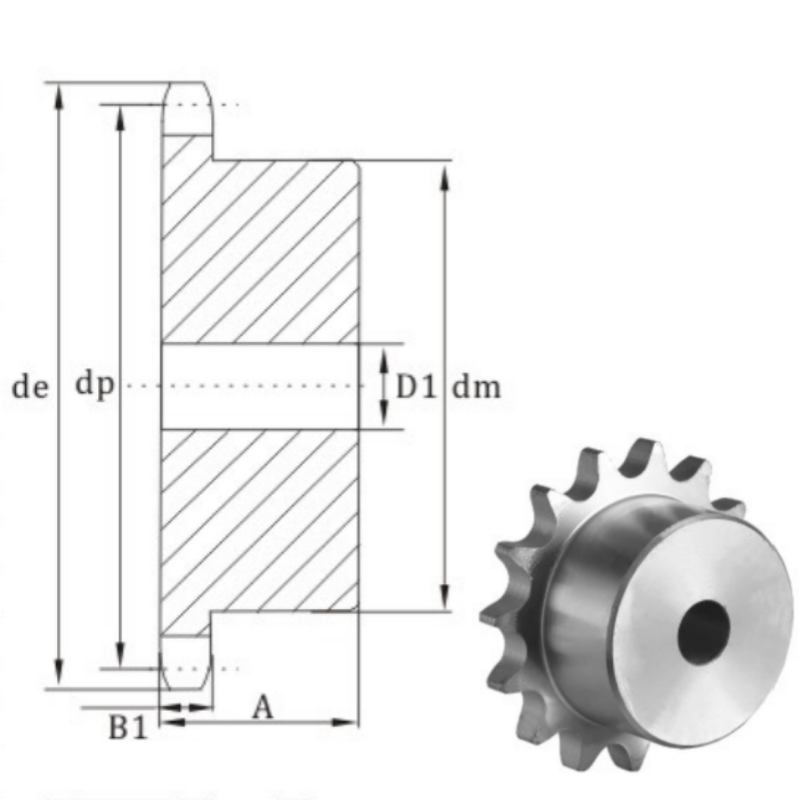

ANSI Chain Sprocket Dimension

ANSI sprockets are manufactured to strict dimensional standards to ensure interchangeability and compatibility. Key parameters include:

Pitch: The distance between the centers of two consecutive chain pins.

Roller Diameter: The diameter of the rollers that engage with the sprocket.

Tooth Width: The width of the sprocket teeth.

Hub Diameter: The diameter of the hub where the sprocket mounts.

Outside Diameter: The total diameter of the sprocket.

Bore Diameter: The internal diameter of the sprocket hole for mounting on a shaft.

Number of Teeth: The count of teeth on the sprocket.

Length through bore: This is the distance within the bored hole on hubbed sprockets. This will be of larger value than the face width and must be long enough to withstand torque from the shaft.

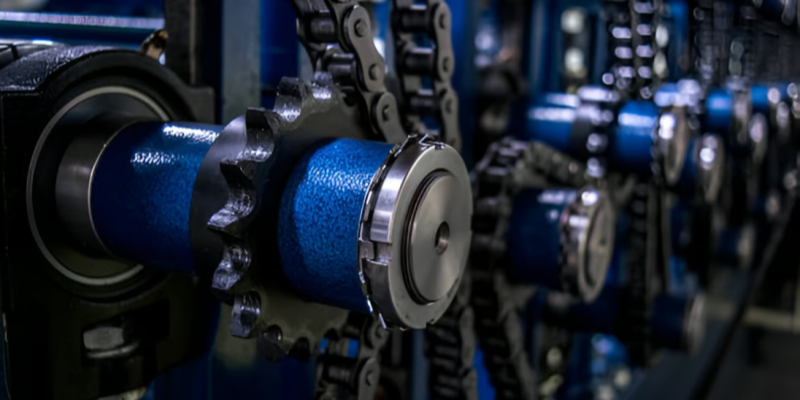

ANSI Chain Sprocket Application

ANSI roller chain sprockets are widely used across different industries, including:

✔ Industrial Machinery-For transmitting torque in manufacturing equipment.

✔ Agricultural Equipment-Used in tractors, harvesters, and other farm machinery.

✔ Conveyors and Material Handling Systems-To drive and guide conveyor chains.

✔Automotive and Heavy Equipment-For durable power transmission in harsh conditions.

How to Choose the Right ANSI Chain Sprocket

When selecting a sprocket, consider the following:

· Chain type and pitch (must match ANSI standards).

· Load and torque requirements.

· Operating environment(temperature,humidity,chemical exposure).

· Material and hub style.

· Quality and precision from the manufacturer.

When selecting ANSI roller chain sprockets, choosing a reliable manufacturer is essential. CTS is a professional industrial chain and sprocket manufacturer with years of export experience and advanced production equipment.

We not only supply standard ANSI sprockets but also provide customized solutions for different tooth counts,bore sizes,materials,and surface treatments.

If you are looking for a trusted ANSI Roller Chain Sprocket supplier, we can be your reliable partner.

Contact us today for expert guidance, technical support, and the latest quotation!

FAQs

What is the difference between ANSI sprockets and metric sprockets?

ANSI sprockets are based on inch measurements, while metric sprockets use millimeters. Their pitch and tooth profiles are different, so they are generally not interchangeable.

What is an ANSI Roller Chain Sprocket?

An ANSI roller chain sprocket is designed and manufactured according to the American National Standards Institute (ANSI) standards. Its tooth profile, pitch, and dimensions follow unified specifications to ensure precise engagement with ANSI standard roller chains.

What materials are ANSI sprockets made of?

Common materials include carbon steel, alloy steel, and stainless steel. Carbon steel sprockets are suitable for most industrial uses, while stainless steel sprockets are ideal for food, packaging,or corrosive environments.