1-10 Grooves V Belt Pulley | Selection and Application

- Share

- Issue Time

- Aug 2,2024

Summary

Discover the differences between 1 to 10 groove V-belt pulleys. Learn applications,advantages,and how to choose the right pulley for your machinery.

What are V-Belt Pulley Grooves

The grooves in a V-belt pulley are the slots that hold the V-belt in place. More grooves mean the pulley can accommodate multiple belts, increasing power transmission capacity.

Different groove configurations—whether single, double, or multi-groove—can significantly impact performance, durability, and suitability for various applications.

Why the Number of Grooves Matters

The number of grooves directly influences:

· Power capacity: More grooves allow more belts, which share the load.

· Reliability: Multiple belts reduce the risk of total system failure.

· Cost and weight: More grooves add cost and weight to the pulley.

· Maintenance: More belts require regular inspection and alignment.

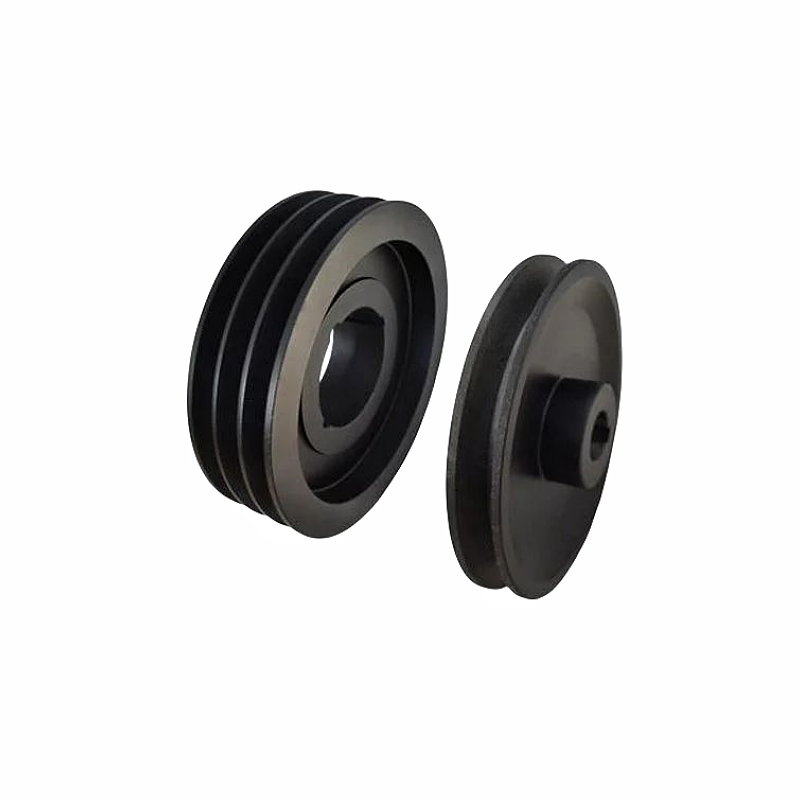

1 to 10 Grooves V-belt Pulley

1 Groove V-belt Pulley

2 Grooves V-belt Pulley

3 Grooves V-belt Pulley

4 Grooves V-belt Pulley

5 Grooves V-belt Pulley

6 Grooves V-belt Pulley

8 Grooves V-belt Pulley

10 Grooves V-belt Pulley

Pulley Materials and Manufacturing Option

V-belt pulleys can be made from different materials depending on performance requirements:

Cast Iron V-belt Pulley

High strength,durability,common in heavy machinery.

Steel V-belt Pulley

Strong and wear-resistant,suitable for high-load applications.

Aluminum V-belt Pulley

Lightweight, good for small machines or where weight reduction is critical.

Surface treatments such as black oxide, phosphate coating, or anodizing can improve wear resistance and extend v-belt pulley life.

V-belt Pulley Installation and Maintenance Tips

✔ Always align pulleys properly to avoid belt wear.

✔ Maintain correct belt tension for maximum efficiency.

✔ Inspect belts regularly for cracks or wear.

✔ Replace all belts in a multi-groove system at the same time to ensure balance.

Choosing the right groove configuration for your V-belt pulley is crucial for optimizing power transmission efficiency and ensuring the longevity of your system. Whether you're dealing with single, double, or multi-groove pulleys, understanding their unique benefits and applications will help you make the best choice for your machinery needs. The material of the pulleys also plays a role in their performance, with cast iron and steel being common choices for durability.

CTS® is a professional v-belt pulley manufacturer. If you can't find the v-belt pulleys you need, please contact us, and our technicians will help you.

FAQs

Can I replace a single-groove pulley with a multi-groove pulley?

Yes, but make sure your system is designed to handle multiple belts.

What happens if the pulley grooves are worn?

Worn grooves cause belt slippage,noise,and reduced efficiency. Replacing the pulley is recommended.