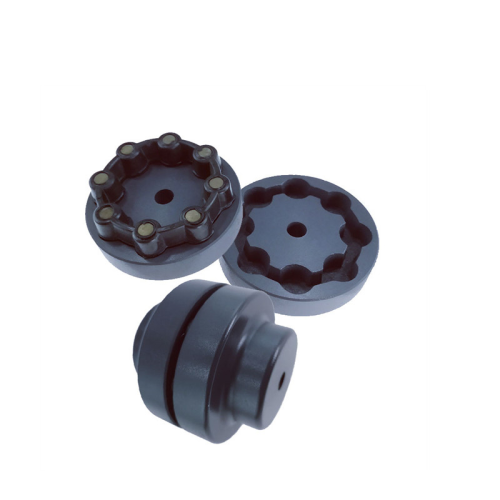

MH 115 Coupling

- Model

- MH 115 Coupling

Item specifics

- Material

- Rubber

- Color

- Natural

- Accuracy

- High precision coupling

- Quality

- Easy Installation and Maintenance

- Interchangeability

- Directly interchangeable with other brands

Review

Description

CTS® MH 115 Coupling

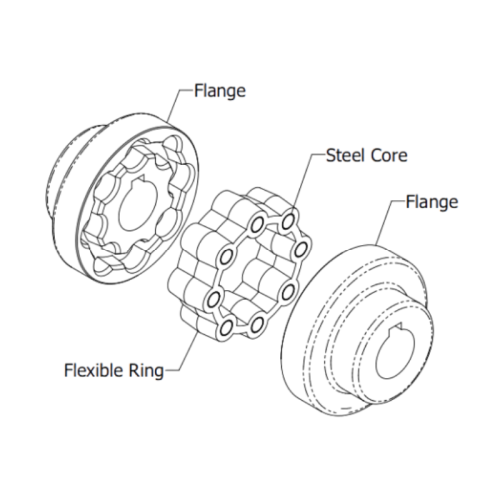

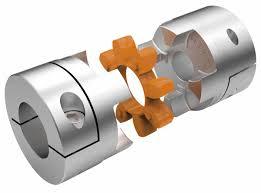

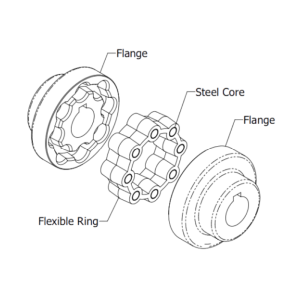

The MH coupling is a versatile and robust shaft coupling designed to accommodate various types of misalignment while providing reliable power transmission. Featuring a flexible ring made of synthetic rubber with reinforced steel cores, the MH coupling effectively dampens torsional vibrations and oscillations, ensuring smooth operation and minimizing stress on connected machinery. Its ability to compensate for misalignment reduces wear and extends the life of bearings and other components. The coupling is suitable for use in a wide range of industrial applications and operates efficiently in temperatures ranging from -40°C to +100°C. The rubber also resists oil, dirt, grease, moisture, ozone, and many chemical solvents. With its simple yet effective design, the MH coupling offers durability, flexibility, and reliable performance in demanding environments.

CTS® high-quality MH Coupling built to keep your machine running!

For a quotation or other information on MH 115 coupling, please contact us and we will be happy to help you.

Quality Assurance:

ISO9001: 2015 and GB/T24001-2016 / ISO14001: 2015.

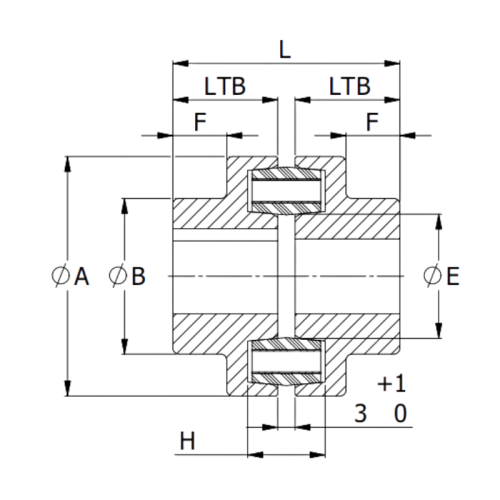

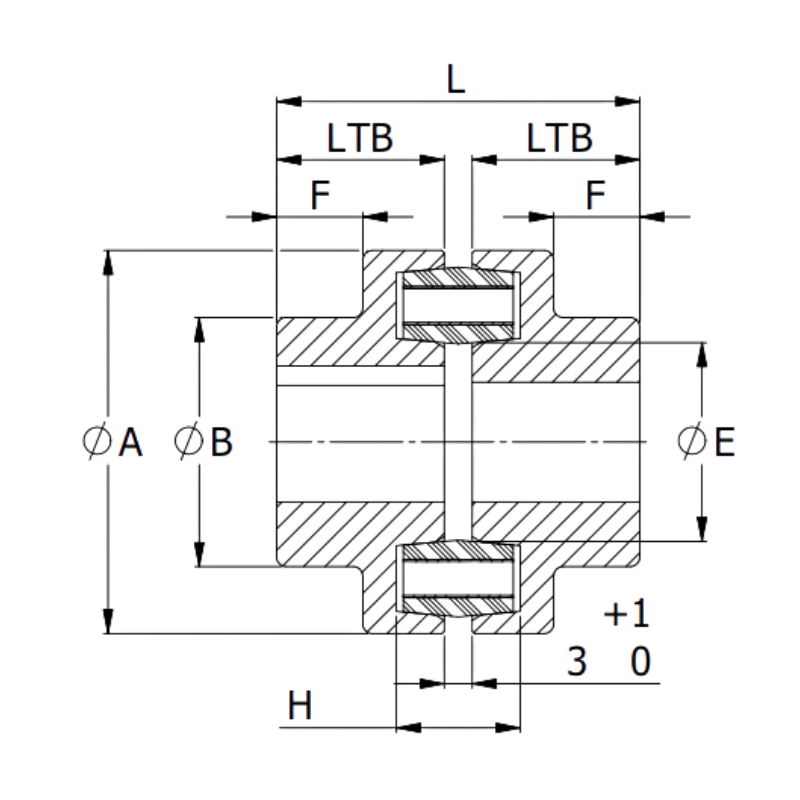

MH 115 Coupling Dimensions

- Rated Torque: 80.0 Nm.

- Max Speed: 4,600 RPM.

- Bore Dia(min): 25 mm

- Bore Dia(max): 45 mm

- A: 115 mm

- B: 80 mm

- LTB: 55 mm

- L: 113 mm

- E: 58 mm

- F: 29 mm

- H: 33 mm

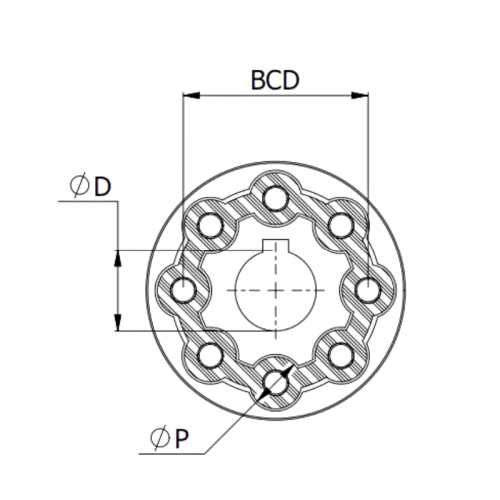

- BCD: 82.0 mm

- P: 23.0 mm

- Total Weight: 8.10 kg

- Moment of Inertia GD^2: 2.70E-02 kg.m^2

Service Factor

Driven Machine | Driver Machine | |||

Operating type |

Examples

|

Electric Motor |

Engine type

|

|

|

4 or more Cyl.

|

3 or less Cyl.

|

|||

Slightly shock |

Centrifugal fan and pumps, agitator for light liquid, light generator, conveyor belt, brewing machinery.

|

1.0-1.2 |

1.5-1.7

|

2.0-2.2

|

Medium shock |

Crane hoists, wood machinery, textile machinery, paper mill machinery, machine tools, centrifugal pump for loaded liquid.

|

1.5-1.7 |

2.0-2.5

|

2.5-3.0

|

Heavy shock | Crusher, shakers, calender, reciprocating conveyor, welding set, heavy rolling mill, rubber machinery. | 2.0-2.2 | 2.5-3.5 | 3.0-4.0 |