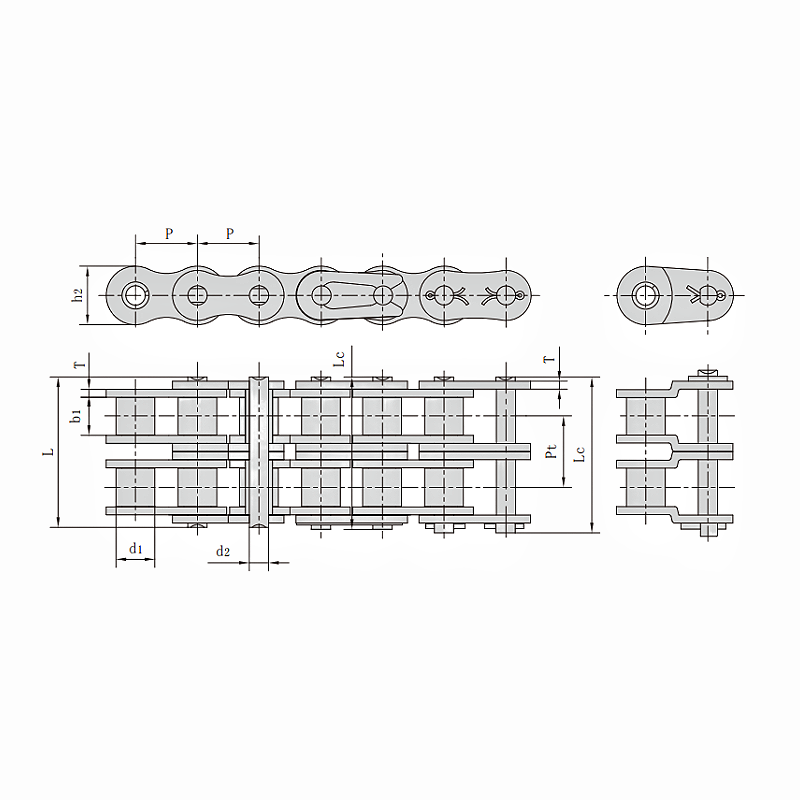

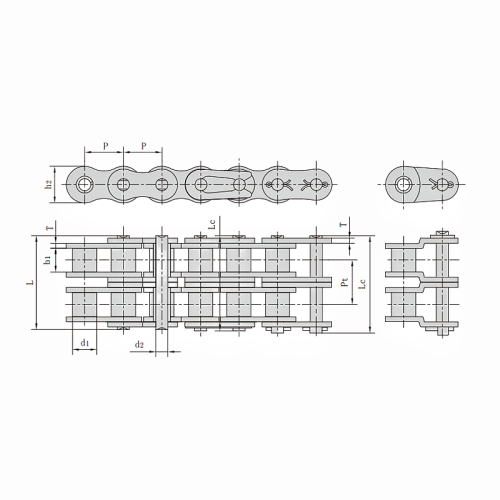

ANSI Duplex Roller Chain

- Model

- Duplex Roller Chain

Item specifics

- Meterial

- Carbon Steel

- Color

- Natural

- Surface Treatment

- Shot Peening/Heat Treatment/Plating/Lubrication

- Accuracy

- High precision roller chain

- Quality

- Durable Roller Chain

- Interchangeability

- Directly interchangeable with other brands

Review

Description

Duplex roller chains are used where increased strength is required, while smaller pitch roller chains are used. Our inventory ranges from ANSI sizes # 25-2 to # 240-2. Multi-strand roller chains are designed to be several times stronger than ANSI or metric equivalent chains. For example, a 50-2 double roller chain is "double" the strength of an ANSI 50-1 single chain. CTS multi-strand roller chain will impress you with its industry-leading tensile strength and coefficient of performance. We have the right double-strand roller chain for your application. In addition, we offer corrosion resistant multi-strand roller chains such as stainless steel chains, nickel plated chains, coated chains, and multi-strand sprockets.

For quotation or other information on ANSI simplex roller chains, please contact us and we will be happy to help you.

Quality Assurance:

ISO9001: 2015 and GB/T24001-2016 / ISO14001: 2015.

Features

- Precision Machined Components

- Low Friction

- Directly interchangeable with other brands

- Uniform Heat Treatment