Comparison of the characteristics of gear shaping and hobbing

- Share

- publisher

- Julia

- Issue Time

- Oct 12,2020

Summary

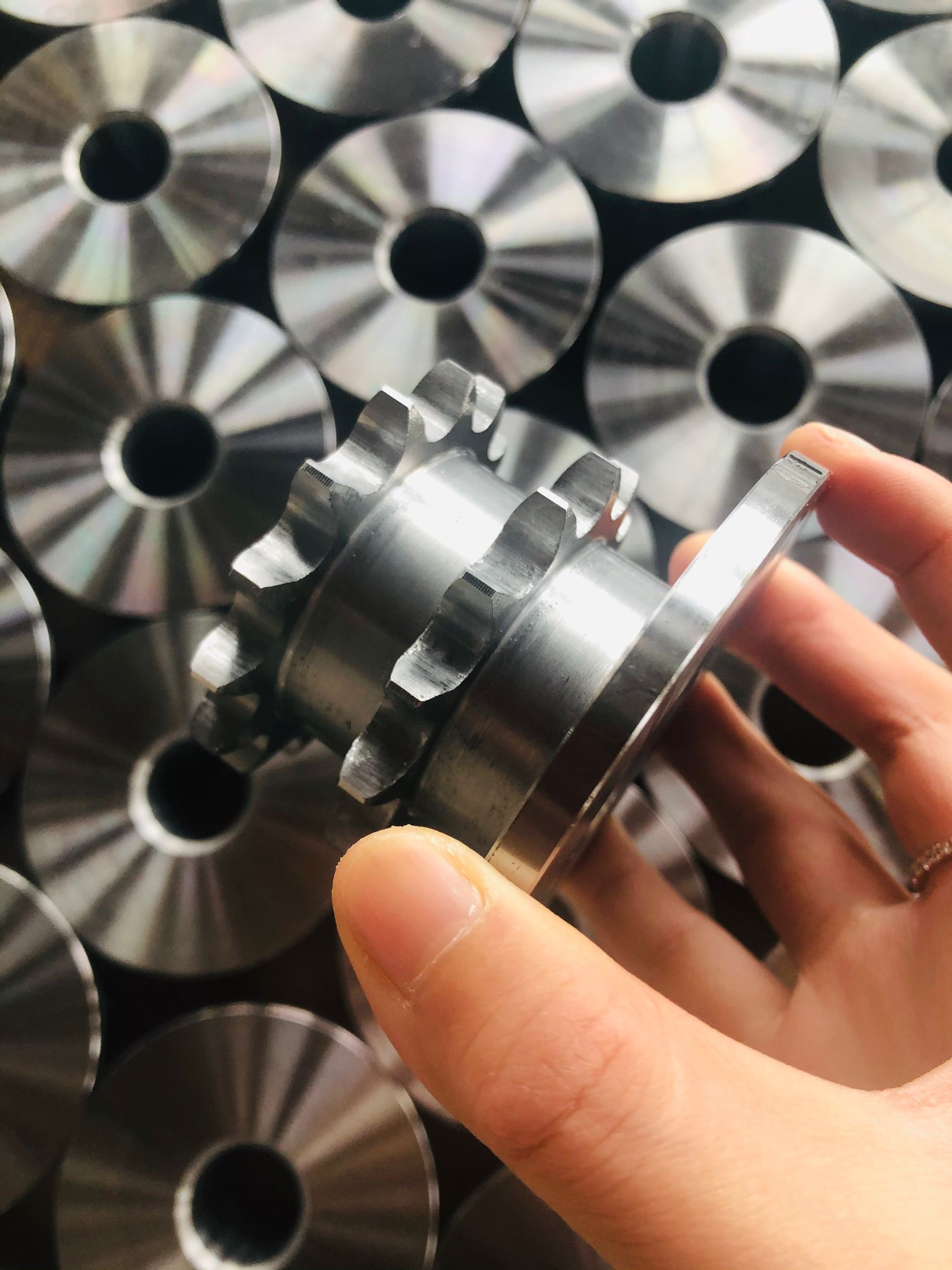

This article explains the comparison of the gear sharping and gear hobbing, YQ-Chinatransmissions is devoted to providing the high quality gear sharpings to help our customers operate the machines more conveniently.

The processing quality of the inserted teeth

1. The tooth profile accuracy of the pinion is higher than that of the hobbing. This is because the shaper cutter can be used to obtain a precise involute profile through the precision gear grinding machine.

2. The tooth surface roughness value after tooth insertion is smaller than the hobbing tooth. The reason is that the circumferential feed amount of the gear teeth is usually small, and the number of cutting edges of the enveloping tooth surface is larger than that of the hobbing teeth during the tooth insertion process, so that the tooth surface roughness after the tooth insertion is small.

3. The accuracy of the tracking motion is worse than the rolling gear. Because in the hobbing, it is generally only a few turns of the cutter to participate in the cutting, all the slots on the part are cut by these teeth; and when the teeth are inserted, the cutters on the shaper cut the workpiece sequentially For each tooth groove, the cumulative error of the pitch on the pinion cutter will be directly transmitted to the gear to be cut; in addition, the error of the machine drive chain makes the angle error generated by the pinion cutter, and the gear after the gear is larger. Motion error.

4. The toothing error of the gear teeth is larger than the hobbing teeth. The tooth misalignment error of the bundle is mainly determined by the parallelism error between the reciprocating motion path of the gear shaping machine main shaft and the rotation axis of the table. The pinion Z complex movement frequency is high, and the wear of the spindle and the sleeve is large, so the toothing error of the gear teeth is often larger than the hobbing teeth.

The productivity of the inserted teeth

When cutting a gear with a large modulus, the gear insertion speed is restricted by the rigidity of the reciprocating inertia bed of the main shaft of the gear insert, and the cutting process has a loss of idle time, so the productivity is lower than that of the hobbing. When machining small gears with small modulus, gears, and narrow teeth, the pinion productivity will be higher than the hobbing.

The application range of the inserted teeth

From the above analysis, it can be seen that the gear teeth are suitable for gears with small machining modulus, small tooth width, high work level and low motion accuracy. It is especially suitable for machining internal gears, pinions, bars and sector gears in multiple gears. However, the helical gear is required to machine the helical gear, which is not as convenient as rolling.

YQ-Chinatransmissions provides a full range of Custom Precision servicesTell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( julia@chinatransmissions.com ) directly for your new project.