How to measure roller chain?

- Share

- Issue Time

- Apr 16,2024

Summary

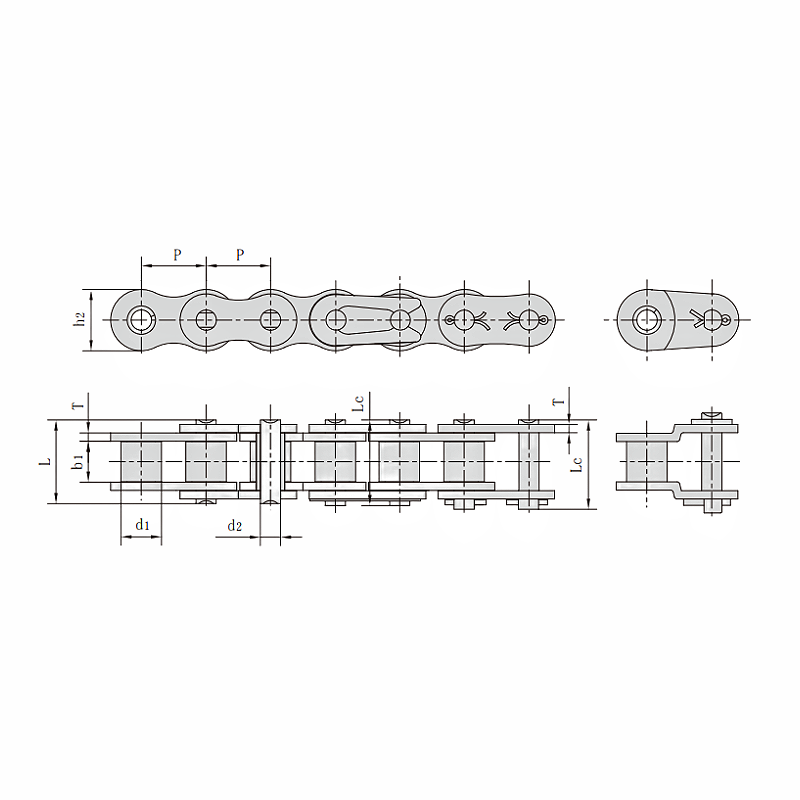

To measure roller chain accurately, adhere to industry standards like ANSI/ASME and ISO British Standards. Given its interaction with sprockets and machine parts, precise measurement is crucial. Measure all components meticulously to ensure correct identification. This includes determining pitch, roller diameter, roller width, inner width, and pin diameter. Consistent adherence to measurement standards ensures compatibility and optimal performance in various applications.

How to measure Roller Chains?

Roller chains are subject to specific measurement standards based on their type. Precision roller chains, vital in diverse applications, adhere to rigorous industry standards like ANSI/ASME and ISO British Standards. Given their direct interaction with sprockets and moving machine parts, precise measurement of roller chain dimensions is imperative. Thus, meticulous measurement of all components is essential to ensure accurate identification and selection of the correct chain for any application.

Tips:

When measuring a roller chain, it's highly recommended to utilize a pair of calipers. This ensures the utmost accuracy in your measurements, crucial for identifying the correct chain size and ensuring compatibility with sprockets and other components. Calipers provide precise and reliable measurements, helping to avoid errors and ensure optimal performance in your application.

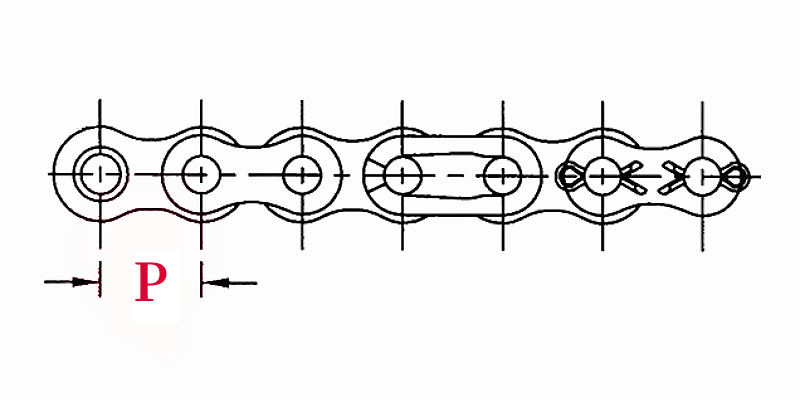

1. Roller Chain Pitch

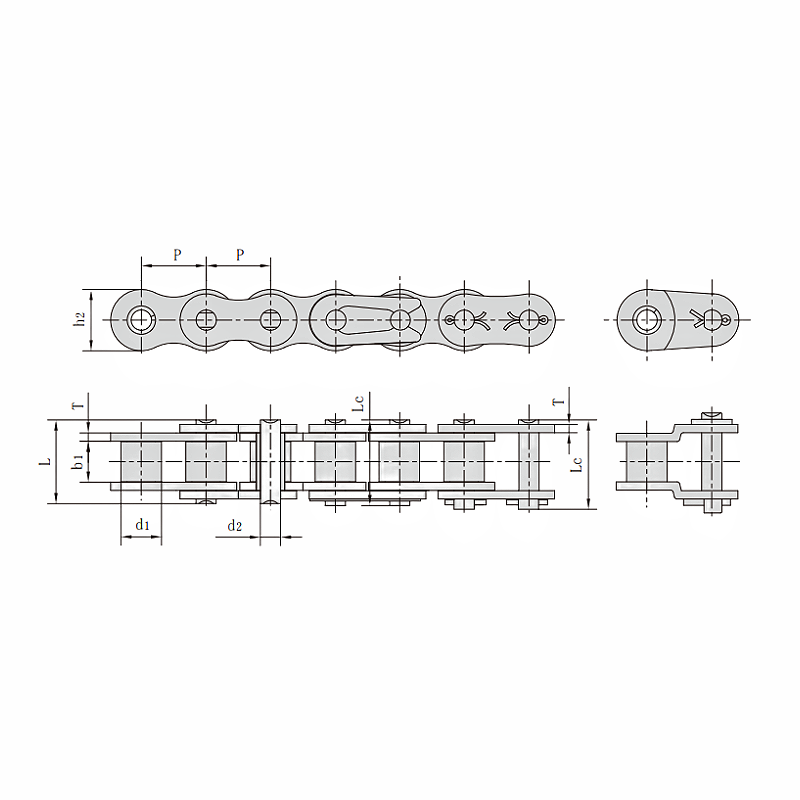

The first dimension to measure is the pitch, denoted as "P" in the drawing. Pitch refers to the distance from the center of one pin to the center of the next pin on the roller chain. This measurement is crucial for determining the size and compatibility of the roller chain with sprockets and other components in the application.

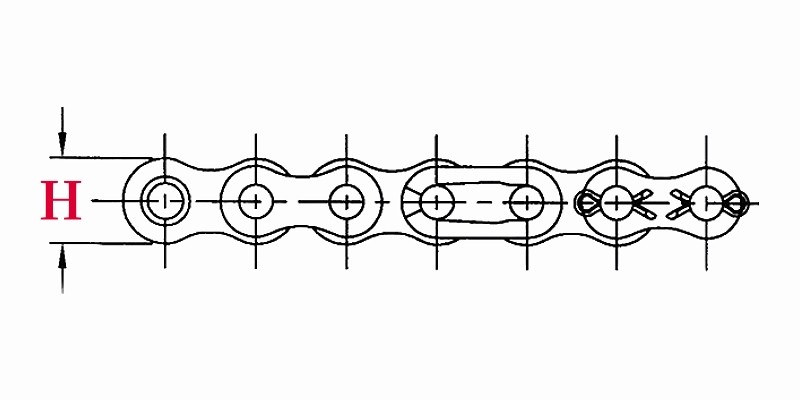

2. Roller Chain Side Plate Height

The roller chain side plate height, represented as "H" in the drawing, is a critical measurement for roller chains. It refers to the height of the chain plates, which can be measured either on the inside or outside of the chain. It's important to ensure that both measurements match. If there is a discrepancy between the inside and outside plate heights, it could indicate a non-standard roller chain. In such cases, it's advisable to inform your customer service representative to explore available options, as we also stock a wide range of non-standard roller chains.

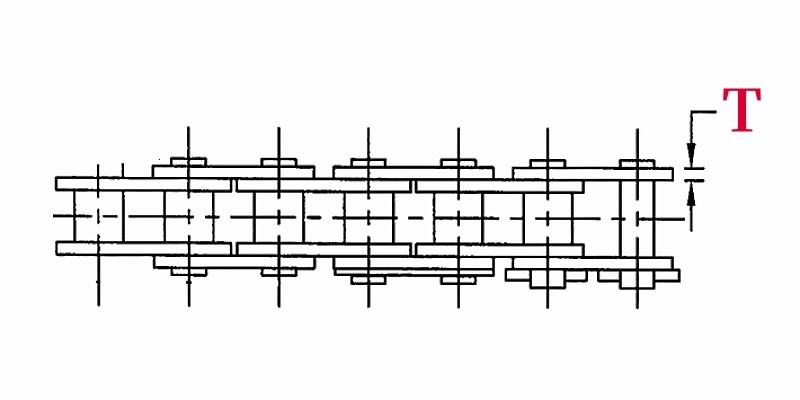

3. Roller Chain Side Plate Thickness

The plate thickness, indicated as "T" in the drawing, is crucial to measure accurately. It's recommended to measure both the inside and outside plate thicknesses, as some ISO and DIN metric roller chains may feature plates with different thicknesses. Additionally, the thickness of the side plate can indicate whether you have a heavy-duty series roller chain. Accurate measurement of plate thickness ensures proper identification and selection of the appropriate roller chain for your application.

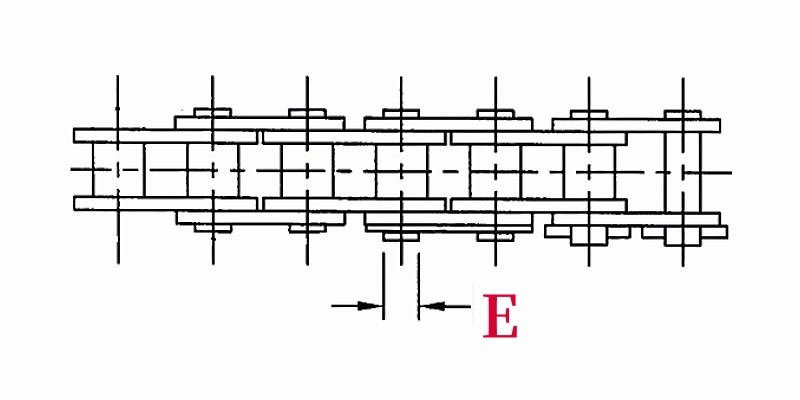

4. Roller Chain Roller Diameter

The pin diameter, denoted as "E" in the drawing, is a crucial measurement when assessing roller chains. It's essential because some specialty roller chains may feature non-standard pin diameters. Ensuring accurate measurement of the pin diameter is important for identifying the correct roller chain for specific applications, especially when dealing with specialty or non-standard chains.

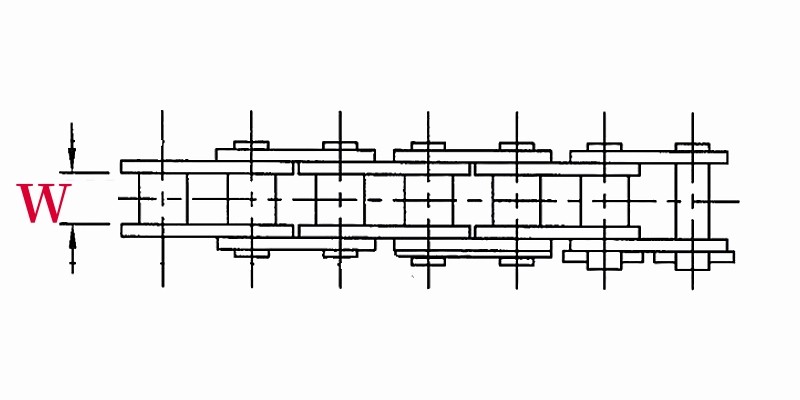

5. Roller Chain Roller Width

The roller width, identified as "W" in the drawing, is a significant measurement for roller chains. In the case of roller-less chains, measuring the inside width of the inner side plates provides the necessary dimension. This measurement is essential for determining the compatibility and proper fit of the chain within the application, ensuring efficient operation and performance.

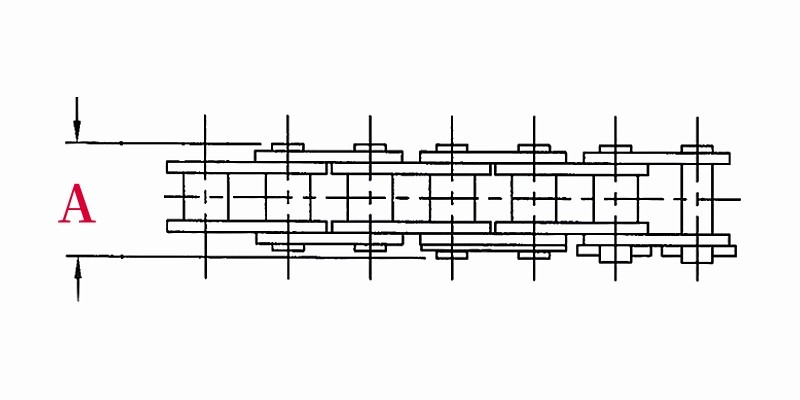

6. Roller Chain Overall Chain Width

The overall width of the roller chain, represented by measurement "A" in the drawing, is a critical dimension to consider. When measuring, it's important to exclude the overall width of the master link or offset link, focusing solely on the width of the chain itself. This ensures accurate assessment of the chain's size and compatibility with sprockets and other components in the application.

ANSI Simplex Roller Chain Technical Data

Metric Simplex Roller Chain Technical Data

For over fourteen years, CTS® has dedicated itself to crafting top-quality roller chain and drive components. Our specialization extends to providing superior power transmission parts and custom-designed products. If you're seeking a reliable Roller Chain solution, look no further. With a full range of ANSI Roller Chains and Metric Roller Chains at your disposal, our experienced team is ready to assist you in finding the perfect fit for your needs. Trust CTS® to deliver excellence and efficiency every step of the way.

To browse our excellent products, please visit our ChinaTransmissions.com or contact us via email at info@chinatransmissions.com or call 0086-18667944319(WhatsApp/WeChat).

If you have any questions, please feel free to contact us, CTS® professional technicians will be happy to help you!